Nyocha banyere usoro mmepe ọhụrụ nke teknụzụ ọgwụgwọ okpomọkụ maka ihe nkedo ụgbọala

1. Mmetụta nke usoro ọgwụgwọ okpomọkụ na-emeziwanye ike ike ọgwụgwụ nke bolts

Maka ogologo oge, ụgbọ ala jikọta yas ejirila njirimara ndị bụ isi nke ụdị dị iche iche, ụdị na nkọwapụta. Nhọrọ ya na ojiji ya gụnyere nyocha nhazi, nhazi njikọ, ọdịda na ike ọgwụgwụ, ihe ndị chọrọ corrosion na usoro mgbakọ, na ihe ndị metụtara ya na-ekpebi àgwà ikpeazụ na ntụkwasị obi nke ngwaahịa ụgbọ ala ruo n'ókè dị ukwuu.

Ndụ ike ọgwụgwụ nke bolts ụgbọ ala dị elu bụ ihe dị mkpa mgbe niile. Data gosiri na ọtụtụ n'ime ọdịda nke bolts na-akpata site na ike ọgwụgwụ, na ọ fọrọ nke nta ka ọ dịghị ihe ịrịba ama nke ike ọgwụgwụ nke bolt. Ya mere, nnukwu ihe mberede nwere ike ime mgbe ike ọgwụgwụ na-eme. Ọgwụgwọ okpomọkụ nwere ike ịkwalite njirimara nke ngwa ngwa ngwa ma mee ka ike ọgwụgwụ ha dịkwuo elu. N'iburu n'uche mmụba na-achọwanye iji ihe nkedo dị elu dị elu, ọ dị mkpa iji meziwanye ike ike ọgwụgwụ nke ihe mkpuchi site na ọgwụgwọ okpomọkụ.

1. Mmalite ike ọgwụgwụ na-agbaji na ihe

Ebe mgbawa mgbawa na-amalite na-akpọ isi iyi ike ọgwụgwụ. Isi iyi ike ọgwụgwụ na-enwe mmetụta nke ukwuu maka microstructure nke bolt, ma nwee ike ịmalite mgbawa ike ọgwụgwụ na obere nha, n'ozuzu n'ime nha 3 ruo 5. Ọdịdị elu nke bolt bụ isi nsogbu. Isi iyi nke ike ọgwụgwụ, ọtụtụ n'ime ike ọgwụgwụ na-amalite site na bolt elu ma ọ bụ n'okpuru ala. Ọnụ ọgụgụ dị ukwuu nke dislocations, ụfọdụ alloying ọcha ma ọ bụ adịghị ọcha na crystal nke bolt ihe, na ihe dị iche na ọka ókè ike nwere ike niile iduga ike ọgwụgwụ mgbawa mmalite. Nnyocha egosiwo na mgbawa ike ọgwụgwụ na-adịkarị mfe ime n'ebe ndị a: oke ọka, ntinye elu ma ọ bụ akụkụ nke abụọ, na oghere. Ebe ndị a niile metụtara microstructure dị mgbagwoju anya na mgbanwe nke ihe. Ọ bụrụ na enwere ike imeziwanye microstructure mgbe ọgwụgwọ okpomọkụ gasịrị, ike ike ọgwụgwụ nke ihe mkpuchi nwere ike ime ka ọ dịkwuo mma.

2. Mmetụta nke decarburization na ike ọgwụgwụ

Decarburization nke bolt n'elu ga-ebelata ike elu ma na-eyi nguzogide nke bolt mgbe quenching, na budata ibelata ike ike ọgwụgwụ nke bolt. Enwere ule decarburization maka ịrụ ọrụ bolt na ọkọlọtọ GB/T3098.1, na oke omimi decarburization akọwapụtara. Mgbe ị na-enyocha ihe kpatara ọdịda nke 35CrMo hub bolts, achọpụtara na enwere oyi akwa decarburized na njikọ nke eri na mkpanaka. Fe3C nwere ike meghachi omume na O2, H2O, na H2 na okpomọkụ dị elu iji belata Fe3C n'ime ihe mkpuchi, si otú ahụ na-amụba akụkụ ferrite nke ihe mkpuchi ahụ, na-ebelata ike nke ihe mkpuchi, na-eme ka micro-cracks dị mfe. N'ime usoro ọgwụgwọ okpomọkụ, a ghaghị ịchịkwa okpomọkụ nke kpo oku nke ọma, ma n'otu oge ahụ, a ghaghị iji ọkụ na-echebe ikuku na-achịkwa iji dozie nsogbu a.

3. Mmetụta nke ọgwụgwọ okpomọkụ na ike ike ọgwụgwụ

Nchekwa nchekasị dị n'elu ihe mkpuchi ahụ ga-ebelata ike elu ya. Mgbe a na-edobe ibu dị ike na-agbanwe agbanwe, usoro nke micro-deformation na mgbake ga-anọgide na-eme na akụkụ nke mgbagwoju anya nke notch, na nrụgide ọ na-enweta dị nnọọ ukwuu karịa akụkụ na-enweghị nchekasị uche, ya mere ọ dị mfe iduga. ọgbọ nke ike ọgwụgwụ na-agbawa.

A na-agwọ ndị na-ekpo ọkụ na-ekpo ọkụ ma na-ewe iwe iji meziwanye microstructure, ma nwee ihe ndị na-arụ ọrụ nke ọma zuru oke, nke nwere ike ime ka ike ọgwụgwụ nke ihe mkpuchi ahụ dịkwuo mma, na-achịkwa nha ọka nke ọma iji hụ na mmetụta dị ala na-ekpo ọkụ, ma nweta mmetụta siri ike dị elu. Usoro ọgwụgwọ ezi uche dị na ya iji nụchaa ọka na mbelata anya n'etiti oke ọka nwere ike igbochi ike ọgwụgwụ. Ọ bụrụ na enwere ụfọdụ afụ ọnụ ma ọ bụ ihe nke abụọ n'ime ihe ahụ, usoro ndị a agbakwunyere nwere ike igbochi ndị bi na ya ịlanarị ruo n'ókè ụfọdụ. Ntugharị nke eriri ahụ na-egbochi mmalite na mgbasawanye nke microcracks.

2. Ngwunye usoro na nhazi usoro maka ọgwụgwọ okpomọkụ

Ndị na-eme ihe na-eme ka ihe dị elu na-arụ ọrụ ụgbọ ala nwere usoro nhazi ọrụ: ọkwa dị elu; ọnọdụ ọrụ siri ike, ọ ga-eguzogide mmetụta nke oke oyi na oke okpomọkụ dị iche iche n'afọ niile yana onye ọbịa ahụ, ma na-eguzogide mmebi nke elu na obere okpomọkụ; Static ibu, ike ibu, ibu ibu, Ibu ibu na gburugburu ebe obibi mgbasa ozi corrosion, na mgbakwunye na mmetụta nke axial pre-tightening tensile ibu, ọ ga-n'okpuru ọzọ tensile alternating ibu, transverse shiee alternating ibu ma ọ bụ jikọtara ekwe ibu n'oge ọrụ. Mgbe ụfọdụ ọ na-enwekwa mmetụta ibu; ibu ọzọ transverse alternating nwere ike ime ka bolts na-atọpụ, axial alternating ibu nwere ike ime ka ike ọgwụgwụ nke bolts, na axial tensile ibu nwere ike ime ka mgbaji bolts na-egbu oge, yana ọnọdụ okpomọkụ dị elu. Ntugharị nke bolts, wdg.

Ọnụ ọgụgụ buru ibu nke bolts dara ada gosiri na agbajiri agbaji n'akụkụ mgbanwe n'etiti isi mkpuchi na nke akwu n'oge ọrụ; a dọpụrụ ha n'akụkụ njikọ nke eri nke bolt akwu na akwu; ma e nwekwara eriri ndị na-akpụ akpụ n’akụkụ akụkụ ahụ e nwere eri. Metallographic analysis: Enwere ferrite ndị ọzọ na-agbasaghị n'elu na isi nke bolt, na ezughị ezu austenitization n'oge quenching, ezughị oke matriks ike na nchekasị uche bụ otu n'ime ihe ndị dị mkpa kpatara ọdịda ahụ. N'ihi nke a, ọ bụ njikọ dị oke mkpa iji hụ na bolt cross-section hardening na ịdị n'otu nke ihe owuwu ahụ.

Ọrụ nke mmanụ na-emenyụ ọkụ bụ iji ngwa ngwa wepụ ọkụ nke ihe mkpuchi ígwè na-acha uhie uhie na-acha uhie uhie ma belata ha na mgbanwe mgbanwe nke martensite iji nweta nhazi martensite dị elu na omimi nke oyi akwa siri ike. N'otu oge ahụ, ọ ghaghị iburu n'uche mbelata nrụrụ bolt na mgbochi gbawara agbawa. Ya mere, njirimara bụ isi nke mmanụ quenching bụ "njirimara jụrụ oyi", nke a na-eji ngwa ngwa jụrụ oyi na ọkwa okpomọkụ dị elu, na ọnụ ọgụgụ dị jụụ na obere okpomọkụ. Njirimara a dabara nke ọma maka quenching chọrọ nke alloy structural steel ≥ 10.9 elu-ike bolts.

Mmanụ na-emenyụ ngwa ngwa na-emepụta ire ere ọkụ, oxidation na polymerization mmeghachi omume n'oge eji, nke na-eduga ná mgbanwe na àgwà jụrụ oyi. Mmetụta mmiri dị na mmanụ ahụ ga-emetụta ọrụ mmanye ahụ nke ọma, na-ebute mbelata nke nchapụta na isi ike nke ihe nkedo mgbe emechara. Mepụta ntụpọ dị nro ma ọ bụ ọbụna na-agbawa. Nnyocha egosiwo na nsogbu nrụrụ nke mmanụ na-emenyụ na-akpata bụ nke mmiri dị na mmanụ na-akpata. Tụkwasị na nke ahụ, ihe dị n'ime mmiri dị na mmanụ na-eme ka emulsification na mmebi nke mmanụ ahụ dịkwuo elu ma na-akwalite ọdịda nke ihe mgbakwunye na mmanụ. Mgbe mmiri dị n'ime mmanụ dị ukwuu karịa ma ọ bụ hà nhata 0.1%, mgbe mmanụ ahụ na-ekpo ọkụ, mmiri a na-anakọta na ala nke mmanụ mmanụ nwere ike gbasaa na mberede na olu, nke nwere ike ime ka mmanụ na-ejupụta tank ahụ na-eme ka ọ pụta ìhè. ọkụ.

Maka mmanụ ọkụ na-ekpo ọkụ ngwa ngwa nke a na-eji na ọkụ na-aga n'ihu na-agbanye eriri eriri, dabere na data njirimara quenching agbakọba na ule nke ọnwa 3, ọ ga-ekwe omume guzobe nkwụsi ike na njirimara nke mmanụ, chọpụta ndụ ọrụ kwesịrị ekwesị nke quenching. mmanụ, ma buru amụma arụmọrụ nke mmanụ na-emenyụ ọkụ. Gbanwee nsogbu ndị metụtara ya, si otú a na-ebelata nrụpụta ọrụ ma ọ bụ mfu n'efu nke mgbanwe na-emenyụ ihe mmanụ, na-eme ka ọ bụrụ usoro nchịkwa nke mmepụta ihe. Ihe omimi nke hardening ozugbo na-emetụta àgwà nke bolt mgbe ọgwụgwọ okpomọkụ gasịrị. Mgbe ike siri ike nke ihe ahụ adịghị mma, ọnụ ọgụgụ dị jụụ nke ihe na-ajụ oyi na-adị ngwa ngwa, na bolt size bụ nnukwu, ihe mkpuchi bolt enweghị ike ịmenyụ ihe niile n'ime martensite n'oge nkwụsị. Nzukọ ahụ na-ebelata ike nke mpaghara obi, karịsịa ike mkpụrụ. O doro anya na nke a bụ ihe na-adịghị mma maka bolts ndị na-ekesa n'otu n'otu nrụgide tensile n'ofe akụkụ dum. Enweghi ike ike zuru oke na-ebelata ike. Nnyocha metalographic chọpụtara na e nwere proeutectoid ferrite na reticulated ferrite n'ime isi, na-egosi na ọ dị mkpa iwusi ike ike nke bolt. Dị ka anyị niile maara, e nwere ụzọ abụọ na-amụba hardenability dịkwuo quenching okpomọkụ; mụbaa hardening nke ihe na-emenyụ ọkụ, nke nwere ike ịbawanye omimi nke ihe nkedo ahụ nke ọma.

Houghto-Quench ka akpan mepụtara ngwa ngwa quenching mmanụ dabere na mbụ ọkara-ọsọ quenching mmanụ, Houghto-Quench G. Houghto-Quench K2000 ka n'ihu mma ya hardening ike, na bụ karịsịa kwesịrị ekwesị maka ojiji na quenching na jụrụ nke fasteners. Omimi na-eju afọ nke hardening.

Okpokoro ihe nkiri vapor nke mmanụ na-emenyụ ngwa ngwa dị mkpụmkpụ, ya bụ, ọnọdụ okpomọkụ dị elu nke mmanụ na-ajụ oyi ngwa ngwa. Njirimara a na-enye ohere ịnweta oyi akwa siri ike maka 10B33 na 45 steel ≤ M20 bolts na M42 nuts, ebe maka SWRCH35K na 10B28 steels, ọ na-ebelata naanị mgbe ọkpụrụkpụ bụ ihe na-erughị ma ọ bụ hà M12 bolts na M30 mkpụrụ nwere ike isi ike. nke isi na isi ike elu nwere obere ọdịiche. Site na nyocha nke nkesa ọnụego jụrụ oyi, na mgbakwunye na ngwa ngwa ngwa ngwa achọrọ n'etiti etiti na ọnọdụ okpomọkụ dị elu, ọnụ ọgụgụ dị ala nke mmanu mmanu nwere mmetụta dị ukwuu na omimi nke oyi akwa siri ike. Nke dị elu na ọnụ ọgụgụ dị jụụ na-adị ala, nke dị omimi nke oyi akwa siri ike. Nke a bara ezigbo uru maka ndị na-eme ihe ike dị elu na-ebu ibu ahụ n'otu n'otu n'ofe akụkụ ahụ dum, a na-achọkwa ka ọ nweta ihe dịka 90% nke usoro martensite tupu ya enwee ọkụ na steeti ahụ kwụsịrị. Ngosipụta ntule gụnyere ihe fọrọ nke nta ka ọ bụrụ ihe ngosi 20 dị ka ebe ọkụ ọkụ, viscosity, uru acid, oxidation resistance, carbon foduru, ash, sludge, quenching cooling rate, and quenching ihie.

Maka bolts nha buru ibu, onye na-emenyụ PAG bụ isi ihe ngwọta, nke na-emezu ihe ndị chọrọ imenyụ nke ọtụtụ ngwaahịa. PAG quenching agent nọ n'ọgbọ a na-esi esi na mpaghara mgbanwe nke martensite, ọnụ ọgụgụ jụrụ oyi dị elu ma enwere nnukwu ihe egwu. Enwere ike ịhazi ya site na itinye uche. Ọnụego jụrụ oyi na ndeksi igodo bụ ihe dịka 300 ℃. N'ịbụ nke dị ala na-ajụ oyi n'ebe okpomọkụ a, ka ike na-esiwanye ike iji gbochie nkwụsịtụ na-eme ka ọ dịkwuo mma na ọkwa nchara dabara adaba. Nkwụsi ike nke ọnụ ọgụgụ jụrụ oyi nke convection n'oge a na-eji ya eme ihe bụ ihe kachasị mkpa iji hụ na ịdị mma nke quenching.

N'ihe atụ nke bolts mbụ ọdịda, enwere ike ịhụ na enwere ntụpọ na eriri nke eriri ndị gbajiri agbaji dị nso na mgbawa ahụ. Isi ihe kpatara ya bụ na a na-atụgharị bolts ahụ n'ụzọ na-ekwesịghị ekwesị. Ihe kpatara ya site na mpịachi; A pụkwara ịhụ obere mgbawa nke omimi dị iche iche na ala nke eri ahụ, na ụbụrụ arụrụ arụ ọrụ na-emepụta ebe mgbakasị ahụ. Ọkọlọtọ GB / T5770.3-2000 "Nhọrọ pụrụ iche maka bolts, screws na studs na nhụsianya dị n'elu na fasteners" na-egosi na mpịachi ndị na-abụghị ihe karịrị otu ụzọ n'ụzọ anọ nke ogologo profaịlụ eri n'elu oghere pitch nke bolts n'okpuru nrụgide bụ. ekwe The mpịachi na wuru-elu nke eriri ala adịghị ekwe ntụpọ, na mpịachi bụ otu n'ime isi ihe na-akpata bolt mgbaji. Ojiji nke oke mmanu nrụgide Houghton maka nhazi eriri bolt nwere ike igbochi ihu wulitere nke ọma ma belata itinye uche na nchekasị, si otú ahụ na-enyere aka melite ndụ ike ọgwụgwụ nke bolt.

3. Nchedo elu na mmepe teknụzụ nke ngwa ngwa ụgbọ ala

Ihe ngbochi n'ụgbọala, ọkachasị bolts na-ekechi, eriri ọkpọkọ, mgbachi na-agbanwe, wdg, nọ na gburugburu ebe siri ike mgbe a na-eji ya eme ihe, a na-emebikarị ha nke ọma, ọ na-esikwa ike ịgbasa n'ihi nchara. Ya mere, fasteners ga-enwe ezigbo mgbochi corrosion Njirimara. Ụzọ a na-ejikarị eme ihe ugbu a bụ electro-galvanizing, zinc-nickel alloy, phosphating, blackening na dacromet agwọ ọrịa n'elu. N'ihi mmachi na ọdịnaya nke hexavalent chromium na mkpuchi elu nke ihe mkpuchi ụgbọ ala, ọ naghị emezu ụkpụrụ nke iwu nchekwa gburugburu ebe obibi, na ngwaahịa ndị nwere ihe ndị na-emerụ ahụ anaghị anabata ịbanye n'ahịa ahụ, nke na-eme ka ọ dị elu na-enwetụbeghị ụdị ya. ike nke akpakanamde fastener n'elu omume Ụkpụrụ gburugburu ebe obibi chọrọ.

1. Geomet nke zinc-aluminom na-ekpuchi mmiri

Environmentally-enyi na enyi ọhụrụ mkpuchi technology-flake zinc-aluminom mkpuchi Geomet, Enoufu Group emebela a zuru technology dabere na ihe karịrị 30 afọ DACROMET elu mgbochi nchara technology ahụmahụ na mgbe afọ nke nnyocha na mmepe. Nkà na ụzụ ọhụrụ nke ọgwụgwọ elu chromium --- GEOMET.

Usoro mgbochi nchara, usoro ihe nkiri ahụ nke Gummet na-emeso bụkwa otu ihe ahụ dị ka ihe nkiri Dacromet na-emeso ya. A na-ekpuchi mpempe ọla ndị ahụ n'ígwé iji mepụta ihe nkiri jikọtara ya na nrapado dabeere na silicon iji kpuchie mkpụrụ.

Uru nke Geomet: Nrụ ọrụ, mpempe ígwè dị elu na-eme ka bolts Geomet na-eduzi. Agba mgbanwe agba, Geomet nwere ike iji dị ka primer maka ọtụtụ agba gụnyere electroplating. Nchedo gburugburu ebe obibi, ihe ngwọta nke mmiri, enweghị chromium, ọ dịghịkwa mmiri na-ekpofu ihe na-emepụta, ọ dịghịkwa ihe na-emerụ ahụ na-ahapụ n'ime ikuku. Magburu onwe corrosion eguzogide, naanị 6-8μm film ọkpụrụkpụ, nwere ike iru nnu ịgba ule karịa 1000h. Nguzogide okpomọkụ, ihe nkiri inorganic, na ihe nkiri ahụ enweghị mmiri mmiri. Usoro embrittlement na-enweghị hydrogen, usoro mkpuchi nke enweghị acid na electrolytic, na-ezere embrittlement hydrogen dị ka usoro electroplating nkịtị.

Nkwụsi ike nke ọnụọgụ esemokwu dị oke mkpa maka mgbakọ nke ihe nkwụnye ụgbọ ala. Ihe mkpuchi zinc-aluminom flaky na-adabere na mmiri bụ ihe ngwọta maka ọnụọgụ nke esemokwu. Na ndabere nke mkpuchi zinc-aluminom, a na-etinye ihe mkpuchi inorganic nke mmiri na-arụ ọrụ mmanụ ---PLUS.

2. Electrophoretic mkpuchi teknụzụ

N'ime afọ ndị na-adịbeghị anya, ụfọdụ ihe nkedo nke ụfọdụ ụlọ ọrụ ụgbọ ala ejirila mkpuchi electrophoretic kama ịgafe mgbe emechara electroplating. N'okwu dị mfe, ụkpụrụ nke mkpuchi electrophoretic bụ "mmekọahụ na-emegiderịta onwe ya na-adọta ibe ya", nke dị ka magnet. A na-ekpuchi anode electrophoresis na bolts na anode na agba na-adịghị mma; mgbe cathodic electrophoresis na-ekpuchi ya na bolts na cathode, agba na-akwụ ụgwọ nke ọma. Dị ka anyị niile maara, electrophoretic mkpuchi bụ ukwuu mechanized, gburugburu ebe obibi enyi na enyi, na agba film nwere magburu onwe corrosion eguzogide. Megharia na jigharịa akụrụngwa mmiri iji belata ihe ọkụkụ; wusie ike mgbake nke ọla dị arọ iji belata ihe ọkụkụ; belata VOC (ogige organic na-adịghị agbanwe agbanwe) ihe ọkụkụ; belata oriri ike (mmiri, ọkụ eletrik, mmanụ ọkụ, wdg), ma zute ihe nchebe gburugburu ebe obibi chọrọ iji belata ụgwọ ma melite mma.

A na-etinye ya na akụkụ akpaaka na ngwa ngwa ruo ọtụtụ afọ. Usoro mkpuchi electrophoretic dịtụ tozuru oke. Ọ bụ ngwaahịa na-anọchi electroplating. PPGE Electropolyseal fastener pụrụ iche electrophoretic mkpuchi ihe, EPll / SST 120 ~ 200h anode electrophoresis, EPll / SST 200 ~ 300h cathodic electrophoresis, EPlV / SST 500~1000h EP1000h cathodic electrophoresis. na ZiNC Ọgaranya mkpuchi zinc-ọgaranya organic mkpuchi (na-eduzi).

Site na mmepe nke teknụzụ, na mgbakwunye na mkpuchi cathodic electrophoretic nke nwere ezigbo nguzogide corrosion, mkpuchi anodic electrophoretic nwere ụfọdụ nguzogide ihu igwe na mkpuchi electrophoretic cathodic na nguzogide corrosion ka etinyekwara ya na ahịrị mmepụta. Ka ọ dị ugbu a, a kwadoro usoro mkpuchi electrophoretic nke PPG site n'aka ọtụtụ ụlọ ọrụ na-emepụta ụgbọala, na usoro nke nkọwa agbanweela ka ọ bụrụ ọkọlọtọ jikọtara ọnụ, S424 gbanwere na S451, dị ka Ford WSS-M21P41-A2, S451; General Motors GM6047 koodu G; Chrysler PS-7902 Mcthod C.

Uru nke mkpuchi electrophoretic na-enyere aka na nchekwa gburugburu ebe obibi. Mkpuchi Electrophoretic na-anabata agba nke mmiri, na passivation na-anabata chromium trivalent; meziwanye nguzogide corrosion nke ngwaahịa ahụ, mma mmachi; enweghị oghere nkwụnye, enweghị ịghasa eri, edo film ọkpụrụkpụ, na-agbanwe agbanwe torque uru; omenala electroplating + passivation Usoro, nnu ịgba ule erute banyere 144h. Mgbe ịnakwere zinc phosphating + zinc-ọgaranya primer + usoro mkpuchi electrophoretic cathodic, nnwale ịgba nnu nwere ike iru karịa 1000h, ma ọ bụrụ na anabatara usoro mkpuchi electroplating + cathodic electrophoretic, nnwale ịgba nnu nwere ike iru karịa 500h.

4, nkwubi okwu

N'ọdịnihu, mmepe nke ihe nkwụnye ụgbọ ala ga-abụ nke ahaziri onwe ya, usoro ọgwụgwọ okpomọkụ ga-abụ nke a ma ama na njirimara ọrụ, na nkà na ụzụ nwere ọgụgụ isi, akwụkwọ ndụ akwụkwọ ndụ na nke dị arọ ga-arụ ọrụ dị mkpa. Mmepe nke teknụzụ na akụrụngwa bụ ntọala maka mmepe nke nrụpụta dị elu, ma a ka nwere ọtụtụ ohere maka mmepe. Iji mebie ọdịiche ahụ na ọkwa dị elu nke mba ndị ọzọ, ọrụ ahụ ka na-arụsi ọrụ ike, ọrụ ahụ dịkwa arọ ma dị ogologo.

Njikọ na akụkọ a : Nyocha banyere usoro mmepe ọhụrụ nke teknụzụ ọgwụgwọ okpomọkụ maka ihe nkedo ụgbọala

Nkwupụta Mweghachi: Ọ bụrụ na enweghị ntuziaka pụrụ iche, akụkọ niile dị na saịtị a bụ nke izizi. Biko gosi isi mmalite maka mbipụtagharị:https://www.cncmachiningptj.com

PTJ® bụ onye nrụpụta ahaziri iche nke na-enye ogwe ọla kọpa zuru oke, ọla akụkụ na akụkụ ọla kọpa. Usoro mmepụta ihe ndị a na-ahụkarị gụnyere idebe ihe, ịkwa akwa, ịkwa ọla kọpa, waya edm ọrụ, etching, akpụ na-ehulata, na-ewe iwe, na-ekpo ọkụ na-arụ ọrụ na ịpị, na-etisa na ịkụ ọkpọ, na-akpụgharị eri na ịkwa akwa, ịkwa osisi; multi spindle machining, extrusion na ígwè foring na stampụ. Ngwa gụnyere ụgbọ ala ụgbọ ala, ndị na-eduzi ọkụ eletrik, eriri coaxial, ndị na-efegharị efegharị, ihe transistor, tubes microwave, tubes enweghị oghere, na ntụ ntụ metallurgy tankị extrusion.

PTJ® bụ onye nrụpụta ahaziri iche nke na-enye ogwe ọla kọpa zuru oke, ọla akụkụ na akụkụ ọla kọpa. Usoro mmepụta ihe ndị a na-ahụkarị gụnyere idebe ihe, ịkwa akwa, ịkwa ọla kọpa, waya edm ọrụ, etching, akpụ na-ehulata, na-ewe iwe, na-ekpo ọkụ na-arụ ọrụ na ịpị, na-etisa na ịkụ ọkpọ, na-akpụgharị eri na ịkwa akwa, ịkwa osisi; multi spindle machining, extrusion na ígwè foring na stampụ. Ngwa gụnyere ụgbọ ala ụgbọ ala, ndị na-eduzi ọkụ eletrik, eriri coaxial, ndị na-efegharị efegharị, ihe transistor, tubes microwave, tubes enweghị oghere, na ntụ ntụ metallurgy tankị extrusion.

Gwa anyị ntakịrị gbasara mmefu ego ọrụ gị yana oge nnyefe a tụrụ anya ya. Anyị ga-eme atụmatụ gị iji nye ọrụ kachasị ọnụ ahịa iji nyere gị aka iru ebumnuche gị, ị na-anabata ịkpọtụrụ anyị ozugbo ( sales@pintejin.com ).

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

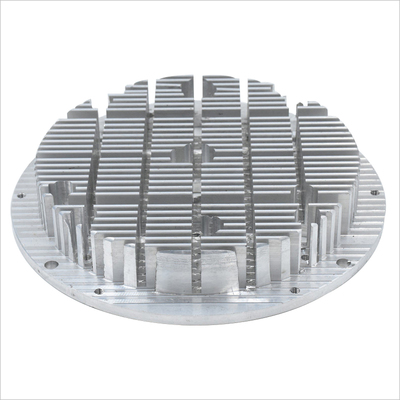

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo