Zuru ezu ihe atụ Of aro machining Technology

Zuru ezu ihe atụ Of aro machining Technology

| Nwa nke usoro nkọwa na akwu akụkụ ahụ metụtara ịdị mma nke ihe eji arụ ọrụ, nrụpụta ọrụ na uru akụ na ụba. |

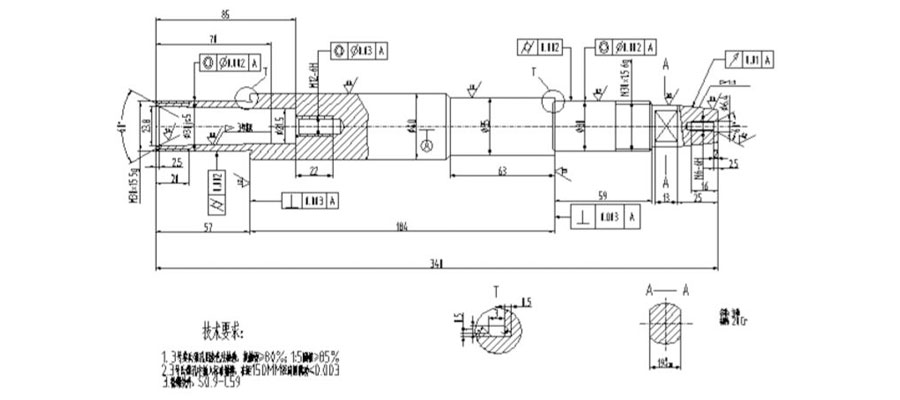

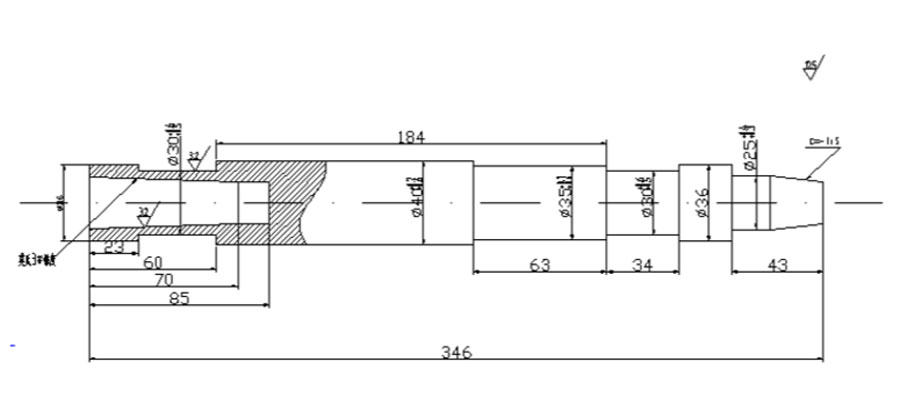

Na nzaghachi maka ihe ndị a chọrọ n'elu, ihe ndị a bụ otu ihe atụ. A carburizing spindle (foto dị n'elu), 40 iberibe kwa ogbe, ihe 20Cr, ma e wezụga nke ime na mpụga eri S0.9 ~ C59. Usoro carburizing dị mgbagwoju anya karị, a ga-esekwa eserese nke usoro ahụ maka usoro mmekpa ahụ (eserese).

Nwa nke usoro a kapịrị ọnụ na ngalaba osisi nwere ezigbo njikọ, nrụpụta ọrụ yana uru akụ na ụba.

Akụkụ nwere ike ịnwe ọtụtụ usoro nhazi dị iche iche, mana naanị otu n'ime ha nwere ezi uche. Na Nwa nke machining usoro nkọwapụta, ihe ndị na-esonụ ga-kwuru.

- 1.Na nyocha usoro nke ịbịaru akụkụ, odi nkpa ighota ihe omuma nke ihe omuma, nkenke, ihe omuma, ogwu oku, wdg, na imuta ihe omuma nke nzuko ahia, uzo ihe ndi ozo na nnabata.

- 2.Processingzọ nhazi nke akụkụ carburizing bụ n'ozuzu ya: ịcha → na-arụ ọrụ Alizing na-emezi ihe → na-eme ihe ike → na-emecha removal carburizing → nhazi mwepụ carbon (maka akụkụ nke na-adịghị mkpa iji meziwanye ike) Na-emecha.

- 3.Nhọrọ nhọrọ siri ike: Ọ bụrụ na e nwere igwe na-enweghị igwe, a ga-ahọta ya na-enweghị ya ka ọ bụrụ ntụpọ siri ike. Maka mgbanaka mgbanaka nke ekwesiri ime ya na elu elu, a na-edozi ihu ala kachasị dị ka ntinye ọrụ. Ma họrọ ebe dị larịị, ka ọnụ ụzọ ámá dị. Họrọ elu siri ike ma nwee ntụkwasị obi dị ka ntụpọ na-adịghị mma, ebe ntụ ntụ na-enweghị ike ịmegharị.

- 4.Ezi nhọrọ benchmark: iji mezuo ụkpụrụ nke usoro iheomume, dị ka o kwere mee ịhọrọ ntọala imewe ma ọ bụ nchịkọta mgbakọ dị ka benchmark bench. N'ikwekọ na ụkpụrụ nke benchmarking. Jiri otu ntụkwasa ọkwa ahụ dị ka o kwere mee n'ọtụtụ arụmọrụ. Dị ka o kwere mee, ntinye ọnọdụ dabara na ntụle ntụgharị. Nhọrọ nke oke nkenke, ebe kwụsiri ike na nke a pụrụ ịdabere na ya bụ akara aka dị mma.

Usoro ntinye igwe

1. Ntughari

Ngwa akụrụngwa: CA6140, Mohs Nke 3 reamer, Mohs Nke 3 nkwụnye nlele 1: nlele 5

Usoro ọdịnaya: dị ka usoro ihe osise na-atụgharị na nha

- (1) A na-agbapu oghere etiti φ2 n'otu njedebe.

- (2) 1: 5 taper na Mohs 3 # n'ime cone agba ule, kọntaktị elu> 60%.

- (3) Mbadamba nke dị n'èzí nke ọ bụla dị n'èzí ga-agafe agaghị agafe 0.1 na radial nke oghere etiti.

Mara: N’ikpeazụ lelee

2.ku ụra

Usoro ọdịnaya: ọgwụgwọ okpomọkụ S0.9-C59

3.Ha

Usoro ọdịnaya: deturningbonization. Otu njedebe ejidere, otu njedebe hiwere isi

- (1) Ihu ihu nke ntụgharị ga-eme ka o doo anya na ogologo nke njedebe ziri ezi nke φ36 ruo na njedebe nke aro ahụ bụ 40

- (2) Drgba mkpọpu ala oghere type5B

- (3) Ntughari

- (4) Ọgwụgwụ ihu nke mbịne, were a ngụkọta ogologo nke 340 ka size, -aga n'ihu na-akuakuzinwo miri emi 85, 60 Celsius chamfer

4. Ntughari

Ngwa akụrụngwa: CA6140

Usoro ọdịnaya: otu clip na otu n'elu

- (1) Na-atụgharị M30 × 1.5-6g eriri aka ekpe nnukwu dayameta na -30JS5 ka -30 + 6.0 +5 .0 ++

- (2) Na-atụgharị -25 ka -25 + 0.2 + 0.1 ogologo 43

- (3) Na-atụgharị -35 ka -353 + 0.4 + 0.3

- (4) Ntughari uzo na-egweri

5. Ntughari

Usoro ọdịnaya: Ntugharị, otu clip na otu elu

- (1) Nnukwu dayameta nke eri M30 × 1.5-6g na φ30JS5 ruo -30 + 0.6 + 0.5

- (2) Na-atụgharị -40 ka -40 + 0.6 + 0.5

- (3) Turngbanye egweri wheel overtravel oghere

6.Mgba

Usoro ọdịnaya: Igwe igwe 19 + 0.28 abụọ dị nha

7.Ọgwụgwọ

Usoro ọdịnaya: ọgwụgwọ okpomọkụ HRC59

8. Nnyocha

Usoro ọdịnaya: Gri egweri oghere etiti abụọ

9.Eghe na-egweri

Ngwa akụrụngwa: M1430A

Usoro ọdịnaya: ndụmọdụ abụọ dị elu, (a na-egbochi njedebe ọzọ na cone)

- (1) egweri egweri nke φ40 n'èzí, na-ahapụ 0.1 na 0.15 fọdụrụ

- (2) egweri egweri φ30js nke dị na gburugburu ka to30t + 0.1 + 0.08 (ebe abụọ) na-egweri ihe

- (3) ike ike-egweri 1: 5 taper, na-ahapụ-egweri nkwere

10. Ime na-egweri ihe

Ngwa akụrụngwa: M1432A

Usoro ọdịnaya: jiri mpempe akwụkwọ V (nhazi na mpụta nke ф30js5)

3omo Momo dị n'ime (re-dakọtara Mohs 3 # cone nkwụnye) emecha allowance 0.2 ~ 0.25

11.Ọgwụgwọ

Usoro ọdịnaya: obere okpomọkụ ịka nká ọgwụgwọ (mmiri), na-ewepụ nrụgide dị n'ime

12. Ntughari

Ngwa akụrụngwa: Z-2027

Usoro ọdịnaya: jikọtara ya n'otu njedebe ma tinye ya n'otu isi

- (1) Drilling φ10.5 oghere, itinye ya na ndu ndu, eri anaghị agha

- (2) Ntughari-uzo, mkpọpu ala φ5 mgbata M6-6HH n'ime eriri

- (3) 60 Celsius oghere nke oghere

- (4) malite ịgba aka uwe malite ịgba oghere mkpọpu ala ф10.5 × 25 (eri anaghị agbanwe)

- (5) 60 Celsius etiti oghere, elu ike 0.8

13. Ngwaọrụ

Usoro ọdịnaya:

14. Nnyocha

Usoro ọdịnaya: Oghere nyocha nyocha Ra0.8

15.Eghe na-egweri

Usoro ọdịnaya: workpiece na-clamped n'etiti abụọ n'elu

- (1) Ọma egweri φ40 na φ35φ25 mpụta gburugburu ka size

- (2) Milling M30 × 1.5 M30 × 1.5 aka ekpe na nnukwu dayameta na 30-0.2-0.3-

- (3) Emecha ọkara ф30js5 abụọ ka ф30 + 0.04 + 0.03

- (4) Ọma egweri 1: 5 taper ka size, lelee site agba? Usoro dị ka aka elu bụ ukwuu karịa 85%

16. egwe

Usoro ọdịnaya: workpiece clamping abụọ n'elu, egweri eri

- (1) Mill M30 × 1.5-6g eri aka ekpe ka ha buru

- (2) Igwe M30 × 1.5-6g eri ka nha

17. Nnyocha

Usoro ọdịnaya: Oghere etiti oghere Ra0.4

18.Eghe na-egweri

Ngwa akụrụngwa: M1432A

Usoro ọdịnaya:

- (1) Ọma egweri, workpiece clamping n'etiti abụọ n'elu

- (2) Ntughari nke oma 2-φ30-0.003-0.007 na nha, attentionaa ntị na ndidi nke geometric

19. Ime ụlọ na-egweri

Ngwa akụrụngwa: MG1432A

Usoro ọdịnaya:

A na-arụ ọrụ a na-arụ ọrụ V, na redio dị n'ime nke Mohs 3 na-adabere na 1 -30 ф gburugburu gburugburu (ibudata, itinye ya na mpụga 2-ф30js5), na ihu nyocha kọntaktị agba dị ukwuu karịa 80%. Na-achọ "1" na "2"

20. General

Usoro ọdịnaya: nhicha na mkpuchi mgbochi nchara na mmanụ, vetikal nchekwa nghọta nghọta n'ime workpiece

Pointsfọdụ isi ihe na nhazi nke aro:

- 1.A na-eji oghere etiti abụọ ahụ mee ihe dị ka ntụnye ọnọdụ, nke kwekọrọ n'ụkpụrụ ahụ e kwuru n'elu nke ndagide na benchmarking.

- Akụkụ nke mbụ na-eji gburugburu dị ka ntụpọ dị njọ, ihu njedebe nke ụgbọ ala ahụ na oghere etiti nke mkpọpu ahụ, mgbe ahụ, a na-etinye mpụta nke ụgbọ ala ahụ na oghere abụọ dị ka ebe ntinye, na na taper oghere na-esichara na mpụta gburugburu nke ike ike ụgbọ ala dị ka n'ọnọdu akwụkwọ, nke bụ ụkpụrụ nke ibe akwụkwọ. Igwe ahụ nwere nhazi data nke ziri ezi karịa otu oge. Nke 2 Mohs cone ziri ezi chọrọ dị elu. Ya mere, achọrọ ihe eji arụ ọrụ V iji mezuo nhụjuanya nke geometric na gburugburu dị n'èzí nke 3-ф2js30 dị ka ntụnye ọkwa. Mgbe cone dị n’ime ụgbọ ala ahụ, ụyọkọ na-ejikọ otu njedebe, otu njedebe na-adịkwa n’etiti etiti, a na-ejikwa gburugburu mpụta dị ka ezigbo ntụnye.

- 3.Mgbe ịmechara ma mechaa gburugburu, a na-eji plọg cone, a na-ejikwa oghere etiti nke cone dị ka ntụnye ọkwa maka ịmecha elu okirikiri nke ọkpọ ahụ.

Maka cone ihe ị chọrọ:

- 1.Cone plọg nwere nnukwu nkenke, n'ịhụ na taper elu nke cone plọg nwere nnukwu ogo nke concentricity na ya n'ọnụ onu.

- 2.The cone plọg ekwesịghị-anọchi mgbe echichi iji belata nwụnye njehie mere site ugboro ugboro echichi.

- 3.Onye mpụga nke mpụga nke mpempe mpempe mpempe mpempe akwụkwọ kwesịrị ime n'akụkụ njedebe nke osisi ahụ iji kwado iwepụ na mwepụ nke cone.

- 4. Isi machining aro bụ carburized na obi ike na 20Cr ala-carbon alloy ígwè, na workpiece na-adịghị chọrọ ka obi tara mmiri (M30 × 1.5-6g ekpe, M30 × 1.5-6g, M12-6H, M6-6H), na-ahapụ 2.5-3mm carbon mwepụ oyi akwa n’elu. .

- 5.Mgbe emechara eriri ahụ, enweghị ike ịhazi ya na lathe. Y’oburu na uzo buru uzo kpochapu ma emenyu, owu a gha emebi. Ya mere, eri ahụ anaghị ekwe ka o sie ike, yabụ a ga-ahapụ oyi akwa carbon na dayameta na ogologo nke akụkụ eri na workpiece. Maka eri dị n’ime, a ga-ahapụkwa oyi akwa decarburization 3 mm n’akụkụ ebe ahụ.

- 6. Iji hụ na izi ezi nke etiti ahụ, etiti oghere ọrụ ahụ anaghị ekwe ka obi sie ya ike. N'ihi nke a, ngụkọta ogologo nke oghere bụ 6 mm.

- 7.Iji hụ na egweri ihe na-emezi nke okirikiri nke mpempe akwụkwọ ahụ, a ga-ahazi usoro nke ịmịcha oghere dị n'etiti mgbe a gwọchara ya ọkụ, a chọkwara ịdị mma dị elu Mgbe mpụta gburugburu dị n’ala, gburugburu dị n’arụ ọrụ ahụ na-abụkarị n’ihi njikọ ọnụ oghere abụọ dị n’elu na njehie gbaa gburugburu nke oghere elu ahụ.

- Iji kpochapụ nrụgide na-egweri, a na-ahazi usoro ịka nká dị ala (mmiri) mgbe emechara ike.

- 9. Iji nweta a elu-nkenke elu gburugburu, na-egweri kwesịrị-ekewa n'ime ike ike-egweri, ọkara gụchara, na mma-egweri. A na-ahazi ezigbo egweri na igwe na-egweri igwe.

Njikọ na akụkọ a : Zuru ezu ihe atụ Of aro machining Technology

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo