Chọpụta Coaxiality Method Of Machined pee Parts

Okwu Mmalite na ihe nnọchianya ihe atụ nke coaxiality

|

1. Coaxiality bụ a n'ibu oru okwu na-anọchi anya n'ọnọdu ndidi ke udi na ọnọdụ ndidi nke akụkụ. Ihe ndị dị mkpa bụ axis na axis, oghere na oghere, na axis na oghere. A choro otu uzo ma obu uzo di nkpa, nke putara nchịkwa Otutu uzo di na uzo ya. 2. Egosiputara ihe omuma ya dika uzo abuo: ◎ |

Ihe ojoo nwere ike ibute nke nnukota onyogho

Nkọwapụta nke coaxiality bụ nhazi nke etiti nke gburugburu egosipụtara n'akụkụ obe. Ọ bụrụ na etinyere akụkụ ndị nwere nnukwu njehie coaxiality ma jiri ya rụọ ọrụ, ha nwere ike ghara ịgbakọta n'oge nzukọ. Igwe a gbakọtara nwere ike ịmepụta vibration, ịma jijiji, mkpọtụ oge, nkwụsị na-adịghị agbanwe agbanwe, mmebi nke akụkụ igwe, ma nwee ike imebi nnukwu ihe. A usoro nke n'ibu ọrịa dị ka ihe mberede na mberede, ya mere na ịchịkwa nke coaxiality nke mgbe niile kemgbe ihe dị mkpa nke mma nnyocha nke PTJ Shop Plastics Machining.

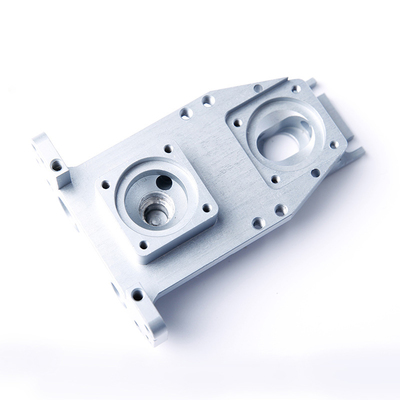

Partsdị akụkụ maka mmụba coaxiality

A ga-eji akụkụ ndị a na-etinye uche na akụkụ ndị na-agbagharị agbagharị, dịka akwus, gias, ohias na akụkụ ndị ọzọ.Ngwa ule

Ọdịdị coaxiality siri ike ịlele. Ngwa anyị na-eji gụnyere onyogho, nhazi atọ, mita ana-agbagọ agbagọ, Irons nwere ọdịdị V, akara ngosi oku, na ọpụrụiche ndozi.

Asurezọ ntụgharị

Nchọpụta nke coaxiality bụ ihe nnwale nke anyị na-emekarị na ọrụ nha. Ihe ndị a bụ mkpirikpi iwebata na usoro nchọpụta nke coaxiality nke shaft na gia nke ụlọ ọrụ mepụtara.

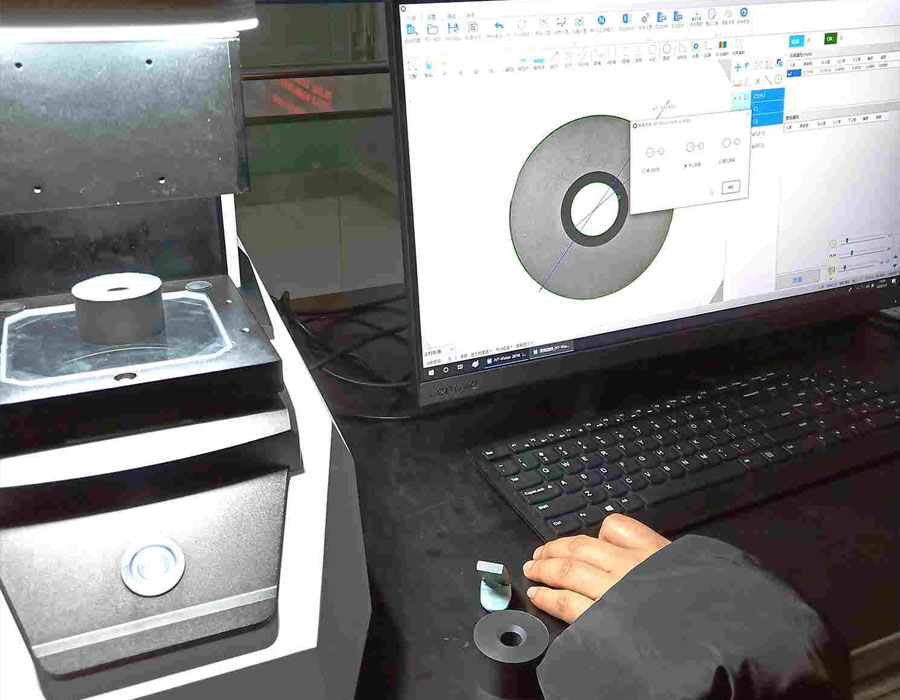

Mzọ iji tụọ coaxiality na imager

- 1. Tụgharịa na kọmputa na-edebe ndị anwale akụkụ na workbench

- 2. Mepee flash button na kọmputa na mbubata usoro ihe omume

- 3. Pịa mpụta dị na mpụta na oghere dị n’ime nke ihe atụ ahụ na oke, wee pịa bọtịnụ mmụba

- 4. Guo coaxiality data, detuo ya, ma mejuputa akuko nyocha!

2. ofzọ iji atụ ihe coaxiality na nhazi atọ (CMM)

- 1. Chọpụta ihe osise nke mbụ wee chọta akara ngosi.

- 2. Idozi ihe peek machining akụkụ ka a tụọ ya na nhazi nhazi atọ ma dozie ya nke ọma.

- 3. Gbanwee nhazi atọ ahụ, dozie isi ya, gbanye kọmputa ahụ, chọta ngwanrọ ngwanrọ kwekọrọ, mepee ngwanrọ ahụ, wee mezie mmemme ahụ.

- 4. Bido ịlele ngwaahịa, guzobe sistemụ nhazi, ma tụọ gburugburu

- 5. Kọwaa benchmark, inyocha ndị tụrụ cylinders, na mgbe ahụ ị pụrụ ịhụ na coaxiality.

- 6. Mbupụ akụkọ nlele ahụ.

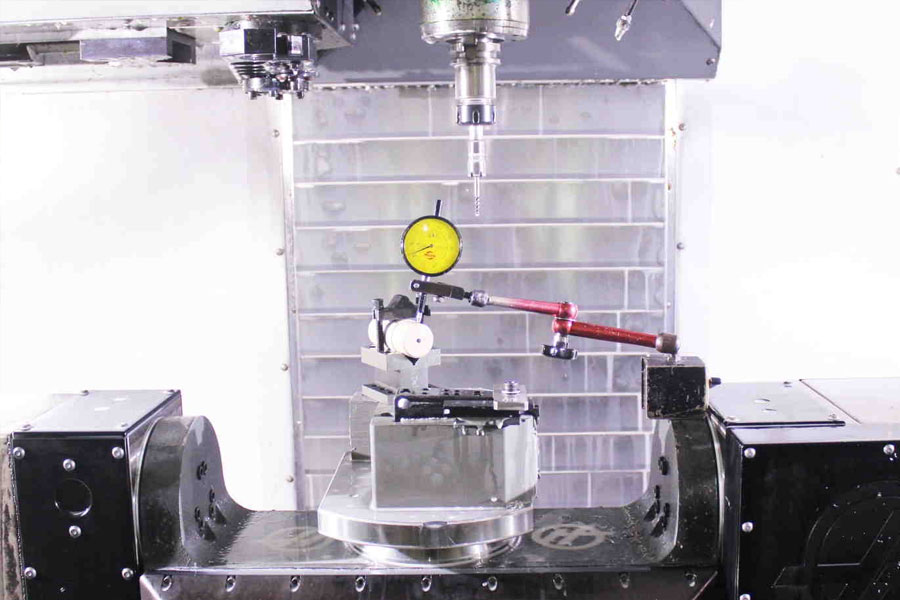

3. Usoro iji tụọ coaxiality na yaw

- 1. Jiri mmiri ọkụ sachaa ihe nlele ahụ wee jiri akwa kpọrọ nkụ hichaa ya.

- 2. Gbanwee ebe di n’agbata uzo abuo nke yaw, nke di ihe dika 8 mm mkpumkpu karịa ogwe aka ya. Dozie oghere dị n'etiti ngwụcha nke mpempe ule ahụ na ọnụ nke yaw. Were aka ekpe gị jiri aka ekpe gị rụọ ọrụ ma jiri aka nri gị mebie ndiiche. Ihe aka nke ngagharị na-agagharị na nsọtụ nke ọzọ nke pendulum na-eme ka ngagharị na-akpụ akpụ ala azụ. Aka ekpe na aka nri na-arụkọ ọrụ nke ọma, ma na-agbanye ngagharị na-agagharị n'ime oghere dị na nsọtụ ọzọ nke ebe ọrụ ahụ!

- 3. Bugharịa ihe iji jiri aka nwalee ya, ma gbanwee ya ngwa ngwa, mana ọdịiche ekwesịghị ịdị oke. Gbaa mbọ hụ na ihe ahụ siri ike. Ma ọ bụghị ya, ọ ga-ebute nsonaazụ ule na-ezighi ezi. Ọ bụrụ na ịchọrọ ịgbanwe mgbatị ahụ, biko rụtụ aka na edemede 2 dị n'elu.

- 4.Wụnye ihe ngosi akara, isi, na nkwụnye, ma hazie akara ọkpụkpọ ahụ ka nyocha ahụ wee metụta ihu elu nke mpempe akwụkwọ ahụ, ma enwere mkpakọ nke gburugburu 0.5-1-XNUMX.

- 5. Jiri nwayọ ma jiri nwayọ jiri aka na-atụgharị ihe eji arụ ọrụ aka n’otu izu, ma na-ahụ ngbanwe nke ihe ngosi ọkpụkpọ, were ọdịiche dị n’etiti ọgụgụ Mmax na ịgụ Mimin dị ka mmezigharị mmekọrịta nke ngalaba, ma dekọọ data ahụ.

- 6. Bugharịa ihe nkwado ihe ngosi oku, họrọ mpụta gburugburu, gbanwee akụkụ a ga-atụle, ma tụọ ọnọdụ anọ dị iche iche dịka usoro akọwapụtara n'elu. Were MAX uru nke ọdịiche dị n'etiti ọgụgụ Mmax na ọgụgụ Mimin dị ka akụkụ Coaxiality njehie.

- 7. Mezue akụkọ nyocha ma hazie akụrụngwa nnwale ahụ.

4. forzọ maka ịchọpụta coaxiality na ígwè V

- 1. Jiri mmiri ọkụ sachaa ihe nlele ahụ wee jiri akwa kpọrọ nkụ hichaa ya.

- 2. Kwadebe ihe mgbochi abụọ nke V nwere otu ogologo na otu ọnụ mbepụ. Debe blọk ndị a kwadebere V dị na okwute mabul ma ọ bụ na tebụl dị larịị.

- 3. Etinye benchmark nke workpiece ka a nwalee ya na V-ụdị uzo nke ngwá

- 4. Wụnye nlele, tebụl isi, na nkwụnye mita, mezie nlele ọkpụkpọ ahụ ka nyocha ahụ wee metụta ihu elu nke mpempe akwụkwọ a tụrụ atụ, ma enwee mkpakọ nke 0.5 - 1 gburugburu

- 5. Jiri aka gị pịa ala ma jiri nwayọ na otu gbanye ihe eji arụ ọrụ otu izu, ma hụta mgbanwe nke akara ọkpụkpọ, were ọdịiche dị n'etiti ọgụgụ Mmax na ịgụ Mimin dị ka njehie coaxiality nke ngalaba ma dekọọ data ahụ.

- 6. Mgbe ahụ megharia isi tebụl, họrọ gburugburu, tụgharịa akụkụ a ga-atụle, tụọ ọnọdụ anọ dị iche iche dịka usoro a dị n'elu, ma were uru MAX dị na ọdịiche dị n'etiti ọgụgụ Mmax na ịgụ Mimin dịka otu. Njehie Axiality

- 7. Mezue akụkọ nyocha ma hazie akụrụngwa nnwale ahụ.

5. forzọ maka ịchọpụta coaxiality nke ngwá ọrụ pụrụ iche

Usoro nchịkọta data na nchịkọta akụkọ

- 1. Buru ụzọ gbakọọ ọnụọgụ njehie ọnụọgụ ọnụọgụ na ngalaba nha, nke ahụ bụ, Δ = Mmax-Mmin.

- 2. Were MAX uru nke coaxiality njehie uru tụrụ na nkebi nke ọ bụla dị ka coaxiality njehie nke akụkụ.

- 3. Mezue nha dịka usoro ndị a dị n'elu ma jupụta ozi dị mkpa na nhapụta nke DUT n'ime akụkọ nyocha ahụ kwekọrọ, ma jiri nke a dị ka ntụaka iji chọpụta ma njehie coaxiality nke akụkụ ahụ na-anabata.

Njikọ na akụkọ a : Chọpụta Coaxiality Method Of Machined pee Parts

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo