Nyocha nke Nhazi Ntanetị Titanium Turbine Profaịlụ Nhazi

Nnyocha nke Nhazi Ngwaọrụ Titanium Turbo Pụrụ Iche Nkọwapụta

|

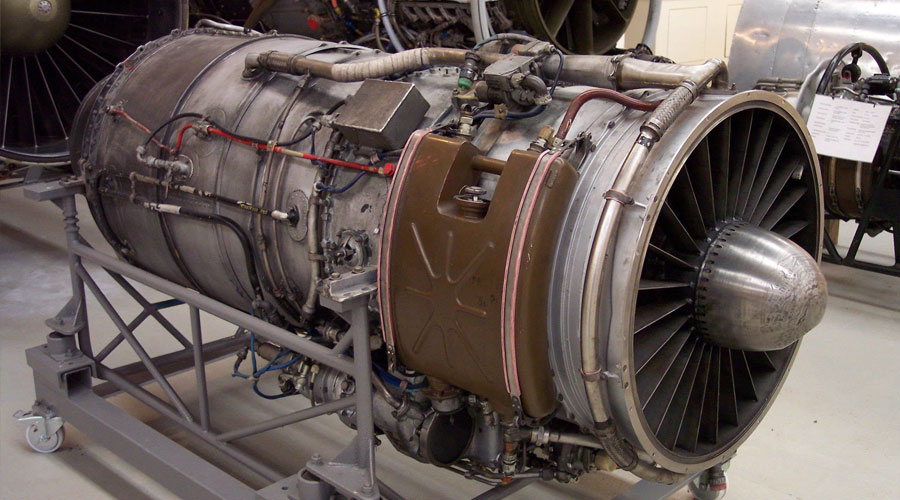

Ihe nkucha nku nke nnukwu engine turbofan engine eruola ihe karịrị 500MM n'ihe gbasara ogologo na nha. Featuredị ihe owuwu a buru ibu na-eme ka ike ikuku na nchekasị na-adịwanye ukwuu n'oge ọrụ ha, ya mere, ọ ghọwokwa nnukwu engine engine nke turbo akụkụ dị ezigbo mkpa. |

Ka ọ dị ugbu a, ọtụtụ injin turbofan ka na-eji akwa titanium alloy damping fan pupụtara. Ọdịdị dị warara na ogologo nke profaịlụ a na-eme ka adịghị ike ya sie ike n'ụdị usoro dị warara na ntuziaka nke ọdọ mmiri ahụ. Iguzosi ike na-adịghị mma nke ihe owuwu ahụ na nnukwu akụkụ nke profaịlụ, ọdịdị nke ihe ahụ siri ike ịhazi, nwere mmetụta dị njọ na ọdịnala machining usoro, nke a na-egosipụta nke ọma na ngwe ngwe ngwe na oke ọnọdụ profaịlụ Ọ na-esi ike ịkwado, arụmọrụ nke polishing ntuziaka dị ala, ike ọrụ dị ukwuu, na ụdị akwukwo a nwere ike ire ọkụ na iwepụ.

Existencedị adị nke nsogbu ndị a dị n'elu bụ mkpirikpi ntụpọ maka mmepụta agụba. Na mmepe na ntinye nke njikọta ọtụtụ axis CNC igwe technology na nnyocha na machining technology nke a agụba profaịlụ, ihe isi ike nke a na-agụba profaịlụ machining e ji nwayọọ nwayọọ gbajiri, na machining àgwà na arụmọrụ larịị ruru a dịtụ ezigbo ala.

Technozọ ụzọ teknụzụ nke CNC si arụ ọrụ nke nnukwu titanium alloy fan agụba profaịlụ

Maka ịkpụzi nnukwu titanium alloy fan agụba profaịlụ, na-atụle akụkụ niile metụtara usoro ọdịnala, nsonaazụ ya nwere akụkụ ndị a.1. Mmetụta nke ihe

- ▶ Ngwongwo titanium nwere obere ihe na-agbanwe agbanwe, nke dị mfe iji mee ka nrụgide nchikota nke ịkpụzi agụba; uwe nke ihu ihu n'oge oge ị na-arụ ọrụ na-eme ka mbelata ikike.

- Or Ajọ thermal conductivity, aka-egbu maramara akọrọ egweri dị mfe iji mee ka nrụrụ nrụrụ, Burns, na ablation.

2. Mmetụta nke usoro agụba

- Overall Mpempe akwụkwọ mkpokọta mkpokọta nke profaịlụ buru ibu, na nkenke kpatara site na-eyi n'oge usoro dum nke ngwá ọrụ na-emetụta nke ukwuu.

- ▶ N'ihi mgbaka na njikwa, akwụkwọ ntuziaka polishing bụ ike-kpụ ọkụ n'ọnụ, na machining ziri ezi siri ike na-ekwe nkwa.

3. Mmetụta nke ọnọdụ ajị anụ

N'ihi mmetụta nke ihe na nkọwapụta, ọ na-esiri ike ịnweta nkesa oke oke, nke na-ebute nsonaazụ ike na-akpata site na mwepụ na-enweghị isi nke oke profaịlụ na nrụrụ nrụgide.4. Mmetụta nke ọrụ ngwá ọrụ igwe

- A-structure Nhazi usoro nke profaịlụ agụba, ntụziaka mbelata nke ngwá ọrụ ahụ, akụkụ nkwụsịtụ ya na nkwụsị ya dị iche, na-akpata mgbanwe na ike ọnwụ.

- Cooling Ọnọdụ obi jụrụ oyi, ezughi oke jụrụ na enweghị jụrụ oyi na-ebute nrụgide nrụgide nrụgide.

N'ịchọ na ihe siri ike nke ịkpụzi nke mma nke nnukwu titanium alloy fans, dabere na uru ọrụ zuru oke nke ọtụtụ teknụzụ CNC machining multi-axis, ụzọ ụzọ ntụgharị kachasị mkpa bụ:

nhazi nke agụba agụm na inyeaka inyeaka profile profaịlụ agụba CNC ike na-egwe ọka machining → Nchekasị Enyemaka aling Ọnọdụ Ndozi Ndozi Control Ọnụọgụ Control CNC Blade Milling → Profaili na-agwụ.

The n'ozuzu usoro echiche guzosie ike site n'elu usoro ụzọ bụ: n'elu CNC ike ike na-egwe ọka usoro ewepu kasị nke oke, na imecha-egwe ọka usoro nwere ezigbo oke nkesa; ncha profaịlụ CNC nkenke egwe ọka usoro ana achi achi geometry nke profaịlụ Na ọnọdụ ziri ezi ihu ọma na-ezukọ ikpeazụ ziri ezi chọrọ nke agụba; mmecha nke profaịlụ agụba na-eme ka o doo anya na ogo nke oyi akwa nke profaịlụ na-ezute ihe achọrọ.

Isi ihe nke CNC milling nke nnukwu titanium alloy fan agụba profaịlụ

Dabere na ihe teknụzụ chọrọ nke profaịlụ agụba, ngwe nke profaịlụ agụba ga-ahụrịrị na ọnọdụ geometric nke ziri ezi nke profaịlụ na-ezute ihe achọrọ ma chọọ nwere ogo adịghị mma. N'otu oge ahụ, mmelite nke arụmọrụ na igwe ọrụ na-elekwasị anya na profaịlụ egwe ọka Ọrụ otu.

Dika nghota nke nkenke ihe eji eme ihe nke ihe di iche iche di iche iche di iche iche di iche iche di nkpa, odi nkpa ka anyi ghota otutu ihe di ka akụrụngwa, ngwa oru, nhazi uzo na ihe ndi ozo. Maka igwe nri nke nnukwu ihe eji acha uhie uhie, ọ dị mkpa ịhọrọ ebe a na-arụ ọrụ axis ise. Ahọrọ a tozuru okè ise-axis linkage agụba machining center nwere ma elu-arụmọrụ machining echiche na machining ziri ezi nkwa ikike.

Maka ịkọwapụta profaịlụ na nnukwu mgbanwe na ntụgharị, enwere ike ịmegharị ọrụ ntụgharị nke akụrụngwa akụrụngwa maka ihe ndị chọrọ ike na-agbanwe agbanwe kwekọrọ na mgbanwe profaịlụ profaịlụ. Sistemụ igwe dị elu nke igwe akụrụngwa na-ebelata oke ọkụ ọkụ ma na-ezere ngwa ngwa ngwa ngwa. , Nke mere na profaịlụ machining nwere ike inweta ezi machining ziri ezi na elu machining mma. Iji gbochie ma belata nrụrụ torsional n'oge ogologo agụba na ịcha, ọ dị mkpa iji hụ na ntụgharị akwus nke pupụtara na n'ihu na azụ ngwụcha nke akụrụngwa nwere a synchronous adiana ọrụ, na nzube bụ ịgbanwe onye ọgwụgwụ clamping na otu njedebe nke omenala agụba machining technology.

Usoro nchikota uzo siri ike iji zere ngbanwe nrụrụ n'oge nkedo nke agụba na nhụjuanya nke profaịlụ agụba na ntụziaka ogologo nke otu njedebe na-akpata na otu njedebe na-esote n'oge ntụgharị ntụgharị. Izute chọrọ nke agụba n'ọnọdu na clamping, inyeaka n'ọnọdu akụkụ na trailing ọgwụgwụ nke agụba nwere nlezianya ọnọdụ ziri ezi chọrọ ikwu na tenon n'ọnọdu akwụkwọ na njedebe n'ihu.

Mgbe emechara profaịlụ ahụ, ihu na azụ nke agụba ahụ n'ihi nrụrụ nrụgide A ga-arụzigharị njehie ọnọdụ dị n'agbata ntụnye ọnọdụ njedebe. Mgbe ị wụnye jigs maka nchapụta profaịlụ nke agụba na ntụgharị rotary na ihu na ngwụcha nke akụrụngwa akụrụngwa ahụ, na mgbe ị chọpụtasịrị na enweghị njehie uche na oghere rotary na ihu na ngwụcha nke akụrụngwa akụrụngwa, ntinye ziri ezi nke ihu na azụ ndozi achọpụtara ma gbanwee site na iji mandrel pụrụ iche. Gbaa mbọ hụ na ndozi na nsọtụ abụọ nwere mmekọrịta ọnọdụ ziri ezi, iji zere nrụgide torsional ọzọ nke ọrụ ntụgharị nke ọrụ ihu na azụ na-agagharị nke akụrụngwa akụrụngwa n'ihi nhụsianya dara ogbenye nke. ndozi. Mwepu ikeike nke profaịlụ agụba bụ iwepụ nnukwu oke ma hapụ otu akụkụ ntinye maka ịmecha. N'okpuru atụmatụ a, ịkpụzi usoro a kwesịrị ịkwado arụmọrụ dị elu. Ise-axis linkage agụba machining center nwere obosara-ahiri machining ọrụ.

Kpụrụ bụ na mgbe ị na-egwe ọka, ahịhịa nke etiti ngwaọrụ adịghị n'akụkụ njikọ nke isi ma ọ bụ elu a na-emegharị, mana na ntụpọ nke ngwa ọrụ na isi ma ọ bụ elu a na-emegharị. Ntuziaka nkịtị dị n'akụkụ ụfọdụ. Nke a na-egwe ọka na-eji a cylindrical ọgwụgwụ na nkume igwe nri, na-egwe ọka bụ a obosara elliptical aak. E jiri ya tụnyere egwe ọka nke isi bọl, otu profaịlụ kachasị elu ma ọ bụ elu dị milled. N'ihe banyere ịdị mma, ebe dị anya n'etiti ụzọ ngwaọrụ sitere na ukwuu. Ya mere, ụdị ọrụ a nwere arụmọrụ dị elu. Na nhazi igwe, usoro ntụgharị nke na-agagharị site n'otu nsọtụ ruo na nsọtụ ọzọ n'ogologo agụba ahụ, ya bụ, a na-eji usoro ntụgharị gburugburu. Site n'ọnọdụ nke arụmọrụ, gburugburu-egwe ọka usoro nwekwara elu machining arụmọrụ tụnyere na longitudinal igwe usoro. Ngwe ọka dị mma nke profaịlụ agụba bụ iji nweta jiometrị dị elu na ọnọdụ ziri ezi, ma n'otu oge ahụ mee ka profaịlụ profaịlụ mebie ihe ụfọdụ achọrọ. Iji belata mmetụta nke "nlọghachi azụ" kpatara site na ịkpụzi ihe nke titanium alloy na mmetụta nke ngwá ọrụ na-eyi na ịkpụzi igwe na-arụ ọrụ n'oge nhazi nke profaịlụ buru ibu, ngwá ọrụ ahụ ga-adị nkọ ma zere ịgbatị ogologo oge nke ngwá ọrụ. N'ihi nke a, ọ bụrụ na ọ ga-ekwe omume, jiri igwe ihe njedebe iji mepụta igwe ogologo nke profaịlụ. Igwe ihe na-eme ogologo oge nwere ike iji ọtụtụ ngwaọrụ ghaa ihu azụ, elu akwụkwọ, ọnụ oriri, na mbubata ọkụ, iji zere iyi akwa nke nnukwu ngwa ọrụ otu, wee mepụta ọkwa ziri ezi na elu nke agụba.

Ihe na-adabaghị adaba na-eme ka njedebe ikpeazụ nke profaịlụ. Mgbe ị na-egwe ọka buru ibu titanium alloy fan rotor agụba, iji meziwanye ọnọdụ ịcha, ihe niile iji zere iyi ngwaọrụ dị mkpa. Na usoro nke nhọrọ nke ngwá ọrụ na nkọwa, n'ozuzu ike alloy ntekwasa cylindrical obi ụtọ egwe ọka eji na-hazie n'ime akụkụ nke agụba n'ọnụ efere, n'ime akụkụ nke onu efere na profaịlụ mgbanwe aak, na ntughari profaịlụ nso na nsọtụ efere 1. Maka oriri na iyuzucha n'ọnụ, họrọ ihe igwe nri na a cylindrical tinyekwa na a ike alloy ntekwasa agụba hazie nnukwu-ebe profaịlụ elu nke agụba akwukwo ite na agụba azụ.

Nhọrọ nke ihe mkpuchi maka ịkpụzi titanium alloy ngwaọrụ dị ezigbo mkpa. Zere iji ihe mkpuchi ihe nwere mmekọ na alloy titanium. Ka ọ dị ugbu a, a na-ejikarị ngwaọrụ ndị a na-ekpuchi PVD eme ihe maka ịkpụkọta alloy titanium. Ihe mkpuchi PVD dị mkpa ma dịkwa mma. Mgbe ha jikọtara na mkpụrụ osisi carbide dị na ya nke ngwaọrụ ahụ, ha ga-ewepụkwa nrụgide fọdụrụnụ. Nchegbu a na-enye aka iji melite mmebi nke ngwá ọrụ ahụ. PVD Enwere ike ijikọ ya na ngwa ọrụ ahụ, nke na-enye aka ịchekwa ọdịdị ihu dị nkọ. Ngwaọrụ PVD nwere ezigbo nguzogide abrasion, kemịkal kemịkal kwụsiri ike, ọ dịghịkwa mfe imepụta ihu igwe wuru ewu. N'oge machining, zuru ezu coolant ga-eji na-ajụkwa ngwá ọrụ na mma mmetụta nke esemokwu, họrọ ezi uche ọnwụ kwa, ma melite mmetụta nke ịcha ike.

Njirimara nke CNC ishingmecha Profaịlụ Titanium Fan Blade

Nchacha profaịlụ na-acha ọkụ bụ iji hụ na profaịlụ profaịlụ na waviness na-agbaso ihe ndị a chọrọ, arụmọrụ ihe owuwu anaghị agbanwe, na akụkụ geometric na ọnọdụ ziri ezi nke igwe na-agbanwe agbanwe agbanweghị n'oge igwe.

N'ihi na n'ezie machining, mmecha nke agụba profaịlụ dabeere na wepụ ndị fọdụrụ ngwá ọrụ akara na-egwe ọka iji nweta ihe a chọrọ ka ike ike na waviness. Ole nke mwepụ nke ígwè n'akụkụ nke ọ bụla nke na-akpụzi elu ekwesịghị ịdị elu karịa 0.05MM. Ugbu a, ojiji nke CNC abrasive belt egweri na polishing igwe ngwaọrụ maka agụba elu finishing bụ a ọzọ tozuru okè usoro maka bara uru machining ngwa, na ojiji nke CNC diamond egweri wheel egweri igwe ngwaọrụ maka agụba elu finishing bụ a ikpe ngwa. Wayzọ.

Ihe kpatara eji ahọrọ usoro igwe a maka itinye ya n'ọrụ bụ n'ihi na ha nwere njirimara nke ha. Nke mbụ, maka machining usoro nke CNC abrasive belt egweri na polishing igwe ngwaọrụ, o nwere ndị na-esonụ e ji mara:

- ▶ Mkpụrụ ọka abrasive nke abrasive ahụ dị nkọ ma na-egweri arụmọrụ dị elu, nke ruru ugboro 10 nke egwe ọka na ugboro 5 nke igwe na-egweri nkịtị;

- ▶ Esemokwu dị n'etiti igwe egweri ihe arụ na obere ọrụ, ihe na-egweri obere okpomọkụ, gburugburu eriri abrasive buru ibu, na ahịhịa abrasive nwere ogologo oge maka mgbasa okpomọkụ. Ọ dị mfe inweta ikuku zuru oke nke ikuku na ịkpụ mmiri, nke nwere ike belata nrụrụ nke ihe ọkụkụ na-arụ na Burns na ablation;

- ▶ Nro nke eriri abrasive na ihe odide ahụ roba n'elu igwe ọrụ na-eme ka o doo anya na eriri abrasive na-arụ ọrụ na-arụ ọrụ ma nwee ezigbo agba ọsọ na nsonaazụ;

- A-ing egweri belt ahụ nwere abamuru nke na-arụ ọrụ, n'ihi na eriri abrasive na-arapara na wiilị ọrụ maka egweri, nha ọrụ abrasive nwere nkwụsi ike ka mma;

- ▶ Ighapu belt abrasive enweghị ike ịhazi ya ruo ogologo oge na nnukwu mwepụ, na abrasive belt nwere ngụkọta nke abrasives dị ụkọ, na-arụ ọrụ ogologo oge na nnukwu ngafe wepụ ga-eri ngwa ngwa abrasives, na ọ dị mkpa ịkwụsịtụ igwe ma dochie eriri abrasive.

Njirimara ndị a kpọtụrụ aha n'elu nke igwerisị abrasive na-eme ka o kwe omume maka nnukwu titanium alloy fan agụba elu polishing iji ghọta nrụpụta ọrụ igwe n'okpuru ọnọdụ njikwa-usoro. Ka ọ dị ugbu a, e nwere ụzọ abụọ ị ga - esi họrọ maka usoro ị ga - eji egwe ihe belụ CNC: nke bụ iji eriri igwe CNC akuku isii na polishing, na nke ọzọ bụ iji sistemụ eriri eriri igwe. igwe. The ngagharị ọrụ nke isii axis CNC belt egweri na polishing igwe yiri ise axis CNC machining center n'oge-egwe ọka.

Ọdịiche dị iche n'etiti belt na-egweri igwe na-arụ ọrụ na igwe na-eme ka ọ dị mkpa iji mezie profaịlụ profaịlụ na usoro agụba. Na Ngabiga n'akuku ọrụ na 2 ntụziaka. Isii axis CNC abrasive belt egweri na polishing igwe nwere sọrọ ọrụ nke profaịlụ egweri na polishing. Mgbanwe ọrụ na-adabere na ngbanwe nke isi ike n'ụdị ntụgharị na-agbanwe agbanwe ma na-esegharị mmiri.

N'ime oge nhicha ahụ, a na-arụ ọrụ na-ese mmiri na-arụ ọrụ oge niile, nke mere na mgbanwe nke nrụgide na-aga n'ihu nwere ike ịchịkwa ya nke ọma site na nrụgide nrụgide, ike ihe na-egweri ike, cylinder nrụgide na-arụ ọrụ mgbe niile na usoro ndị ọzọ iji kwado ihe dị iche na hà nke profaịlụ ọ bụla n'ime otu oke. Polishing machining na-enweghị ebibi ziri ezi nke profaịlụ. Mgbe ị na-eme egweri profaịlụ, a na-ekpochi igwe eji egwu mmiri na-ese mmiri iji kwe ka egweri profaịlụ.

Usoro ngbanwe siri ike nke profaịlụ nwere ike ịgbakwunye ma ọ bụ dochie ọnọdụ ahụ mgbe nkenke nke profaịlụ adịghị mma, a ga-agbanwekwa ọka nke eriri abrasive ejiri dị ka oke. Nke a machining ga-agbanwe The mbụ akụkụ ọnọdụ ziri ezi, na ikwu na-egwe ọka usoro, mwepụ nke oke n'akụkụ peeji ga-emepụta ibu nrụrụ deformation. Ya mere, ọ dịghị atụ aro ka ị jiri ọrụ igwe na-egweri ihe dị n'okpuru usoro a na-egwe ọka nwere ikike ịkwado ziri ezi. Robot CNC abrasive belt polishing usoro bụ na robot jidere agụba na-eme compound ngagharị n'okpuru usoro akara ịrụ polishing machining na a ofu abrasive belt igwe. The machining eji agbara engineering technology. Tupu ịkpụzi ya, robot ahụ na-ejide akụkụ agụba agụba iji lelee profaịlụ nke profaịlụ agụba, mgbe ahụ, usoro ntinye data na-ewepụta usoro njikwa njikwa, wee mechaa mata nchacha nke agụba n'okpuru usoro mmemme. Ka ọ dị ugbu a, n'ihi njedebe nke ngagharị ziri ezi, a na-ejikarị usoro robot abrasive belt egweri dị ka usoro nke ịchacha profaịlụ. Na-egweri usoro nke CNC diamond egweri wiil bụ nke ahụkarị ike na isiike egweri. Igwe akụrụngwa akụrụngwa akụrụngwa ejiri rụọ ọrụ bụ otu ihe ahụ dị ka ebe a na-eme ka ihe na-arụ ọrụ na-arụ ọrụ nke ise. Ihe eji egbu osisi ejiri gbanwee ihe na-egwe ihe na-egosiputa ihe na mbara igwe. Cylindrical egweri wheel. N'oge egweri, obosara-akara machining technology na-eji. Nke a na ụdị machining usoro bụ ike na isiike-egweri. Ebe ọ bụ na wiilị diamond n'onwe ya nwere ikuku ikuku na-adịghị mma, ọ gaghị enwe ike nweta nsonaazụ nke ikpo ọkụ site na ịchekwa ma na-agbanwe usoro jụrụ oyi, yabụ na ọ gaghị adaba maka ịghacha akụkụ nke akụkụ ahụ na nnukwu iwepụ, yana ọbụlagodi Ọ bụ usoro na-ewepu obere oke, ọ dịkwa mfe ọkụ na-egweri nke agụba nke ihe titanium alloy.

Yabụ, mgbe ị na-eji usoro a iji hazie ihu mmiri nke titanium alloy, ọ dị mkpa iji chọpụta akụkụ kachasị mma na ngwa ngwa igwe dị jụụ coolingzọ ahụ ga-adị oke irè. Tụkwasị na nke ahụ, ihe ndị na-egweri ihe siri ike ma na-agbanwe agbanwe nke wheel diamond na profaịlụ ahụ nwekwara "nsọtụ" nke onye cutter ahụ. Ọ bụ ezie na enwere ike ịkwalite ya site na ịhazi usoro ihe omume na nkọwapụta nke igwe egweri, enweghị ike wepu ya kpamkpam. Mmetụta nke ike ọgwụgwụ arụmọrụ adịghị mma, n'ihi ya, a ga-agbakwunye usoro iji kpochapụ elu "ridges". Ọ nwekwara ike ịdị mkpa iji CNC abrasive belt na-egweri na ngwaọrụ ndị na-egbuchasị ihe maka mgbakwunye mgbakwunye n'okpuru njikwa mmemme mmemme. Tụkwasị na nke ahụ, iji ihe abrasive n'efu nke usoro ájá mmiri na-afụ ụfụ maka ntinye mgbakwunye kwesịrị ịbụ usoro enwere ike. N'ihi na n'elu-e kwuru e ji mara nke CNC diamond egweri wheel egweri usoro, ya machining ngwa ka na-exploratory ogbo. Ugbu a, CNC abrasive belt egweri na polishing igwe ngwá ọrụ usoro na-aghọ ndị kasị mma usoro maka polishing nke nnukwu agụba profaịlụ ruru ya ọtụtụ uru. Ihe omuma ya bu na enwere ike iji ya megharia ya. O nwekwara ike ịrụ obere igwe na-egweri okpomọkụ n'okpuru CO2 jụrụ oyi, nke bara ezigbo uru iji zere nsị na mkpochapụ nke nnukwu titanium alloy material agụba profaịlụ.

The ngwa nke CNC egweri na polishing igwe ngwaọrụ agbanweela nnukwu-ọnụ ọgụgụ ntuziaka polishing nke nnukwu agụba profaịlụ, nke na-egwuri dị mkpa iji melite mmepụta arụmọrụ nke nnukwu pupụtara. Mmepe na ntinye nke teknụzụ igwe na-arụ ọrụ na ọtụtụ axis emeela ka ọ dịkwuo mma na ikike ijigide mmesi obi nke igodo njikọ nke nnukwu igwe na-arụ ọrụ profaịlụ, ma nweta nsonaazụ na-eju afọ na arụmọrụ arụmọrụ. Ekwenyere m na site na usoro nyocha na mmelite na-aga n'ihu na teknụzụ akụrụngwa, nnukwu ihe ntanetị na-arụ ọrụ na teknụzụ ga-etolite na nhazi igwe na akpaaka.

Njikọ na akụkọ a : Nyocha nke Nhazi Ntanetị Titanium Turbine Profaịlụ Nhazi

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwangwa nkenke ọrụ ndị ọrụ CNC gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined parts with +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwangwa nkenke ọrụ ndị ọrụ CNC gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined parts with +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

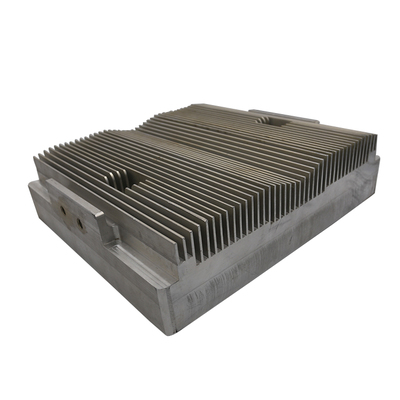

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo