Kedu ihe na-enweghị isi 625

Nkọwa nke Inconel 625

|

Inconel625 bụ ihe ngwọta siri ike wusiri ike na-agbanwe agbanwe nke nwere nickel na molybdenum na niobium dị ka isi ihe na-ewusi ike. Ọ nwere nguzogide corrosion magburu onwe ya na arụmọrụ oxydation. Ọ nwere ezigbo ihe ike na ike ọgwụgwụ site na obere okpomọkụ ruo 980 ℃, ma bụrụ nnu na-eguzogide nrụgide na ikuku ikuku. |

Yabụ, enwere ike iji ya rụọ ọrụ akụkụ akụrụngwa aero engine, akụkụ akụrụngwa aerospace na akụrụngwa kemịkal. The alloy nwere ezigbo nhazi na ọrụ ịgbado ọkụ, ma nwee ike ịnye efere dị iche iche, Ogwe, ọkpọkọ, wires, ibe na na-arụ ọrụs.

Alloy 625 bụ ihe na-eguzogide ọgwụ, na-eguzogide ọgwụ nickel na-eguzogide ọgwụ. Ike magburu onwe ya na ike nke alloy 625 na obere okpomọkụ-1093 Celsius C na-enweta site na nsonaazụ ngwọta siri ike nke nrụpụta ọla kọpa na molybdenum na matriki nickel-chromium. Ezigbo ike ọgwụgwụ na nguzogide nrụgide nrụrụ nke 625 alloy na-erite uru site na ion chloride na ihe.

Inconel 625 ngwa

625 alloy bụ nke a na-ejikarị eme ihe maka ikpuchi ọta ọkụ, igwe ikuku ikuku nke ikuku, eriri ọkụ ọkụ dị n'ime, mkpịsị mmanụ ọkụ, akụrụngwa ụlọ ọrụ kemịkalụ na ngwa mmiri pụrụ iche.

Inconel 625 Corrosion na-eguzogide

625 alloy nwere ike iguzogide ọtụtụ gburugburu corrosive. Na alkaline ngwọta, oké osimiri, mmiri dị ọhụrụ, na-anọpụ iche salts na ikuku, ihe nwere obere corrosion. Nickel na chromium mmiri na-enye ikike antioxidant. Nickel na molybdenum na-enye nguzogide mmebi nke ikuku ndị na-abụghị nke oxidizing. Molybdenum nwere ike n'ụzọ dị irè igbochi olulu na crevice corrosion. Iguzogide nsogbu nke chloride na-emebi emebi bụ nke pụtara ìhè karịsịa. Na elu okpomọkụ, 625 alloy bụ ewekarị flaking ma ọ bụ ọxịdashọn.

Njirimara nke anụ ahụ

Njupụta: 8.44

Nkezi ọkụ a kapịrị ọnụ: 0.098 btu / lb / ° F

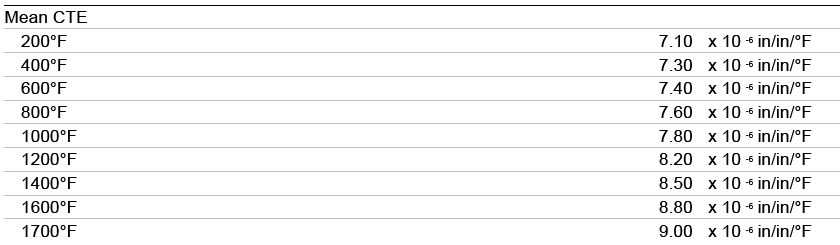

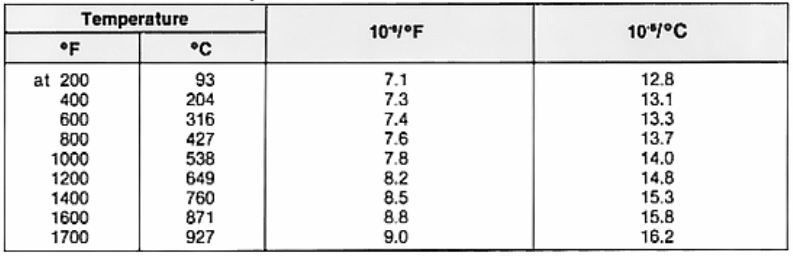

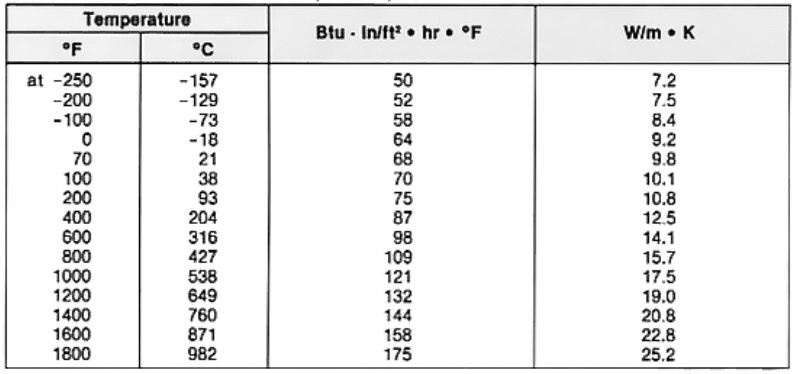

Nkezi onodu ogwugwu oku

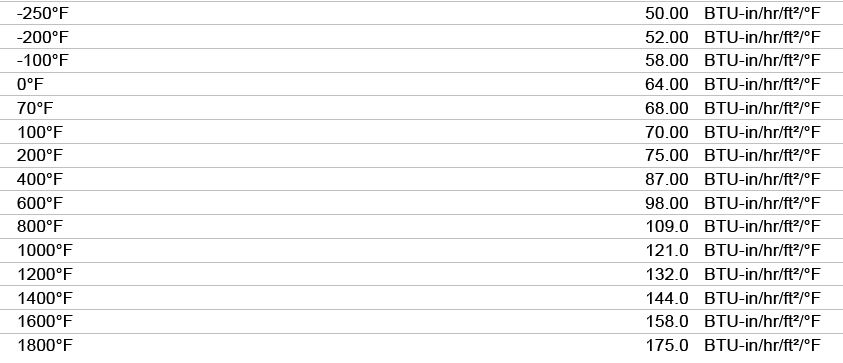

Inconel 625 Igwe ọkụ

Inconel 625 ihe eji eme ihe na-ekpo ọkụ na 1149 Celsius C maka 1 awa

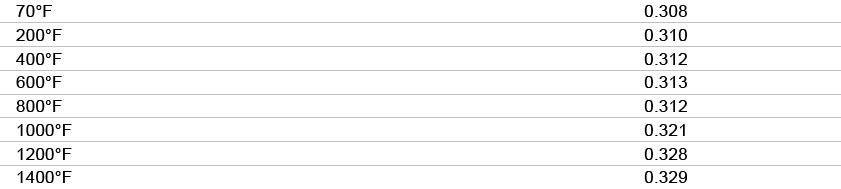

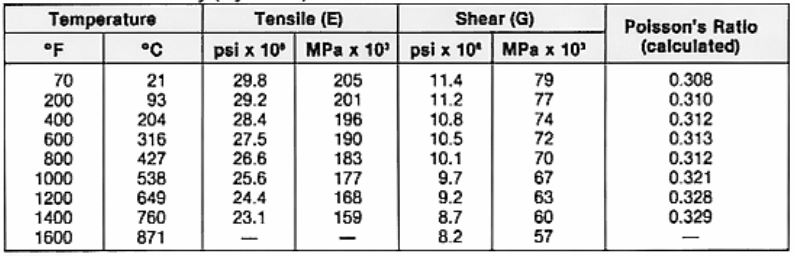

Inconel 625 Poisson ruru

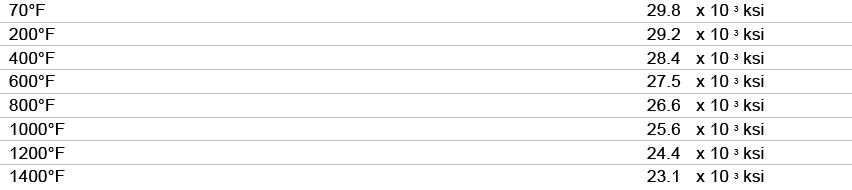

Mgbanwe nke mgbanwe (E)

Modulus nke ekwedo (ike)

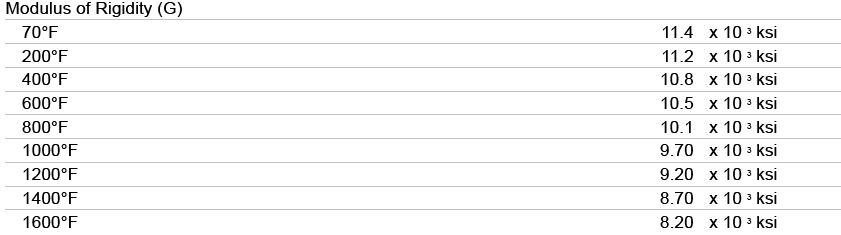

Mgbanwe modul (G)

Inconel 625 Nguzogide

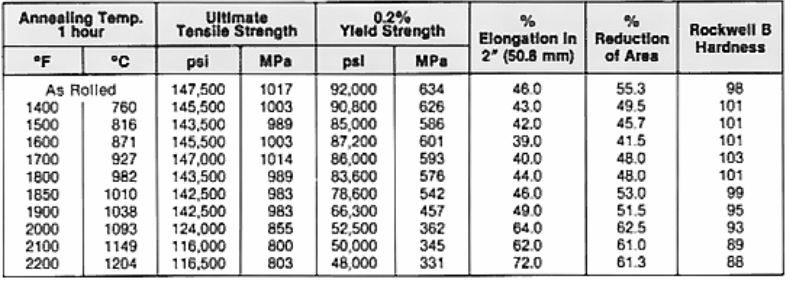

Ihe okpomọkụ mesoo na 1149 ° C maka 1 awa

Curie okpomọkụ: < -320 ° F

Agbaze agbaze: 2350-2460 ° F

Magnetik

Igwe Ọdụdọ (200 Oe): 1.0006Mu

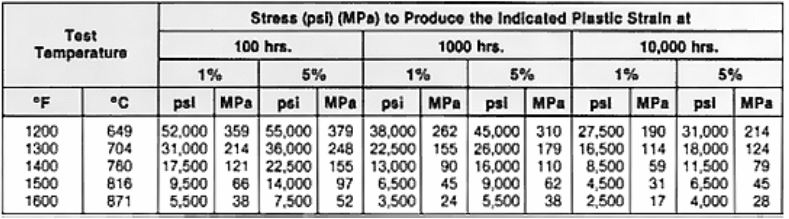

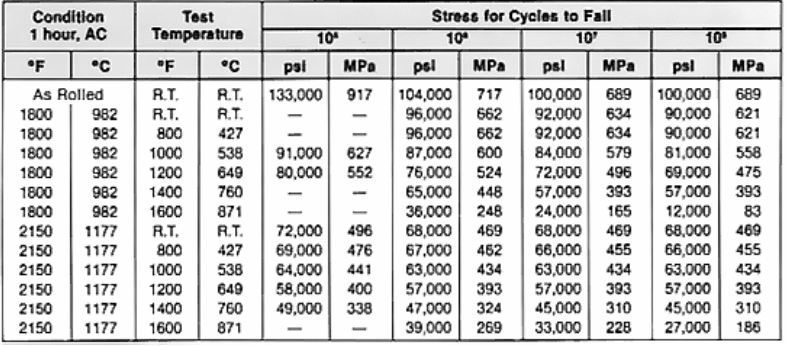

Inconel 625 Creep arụmọrụ

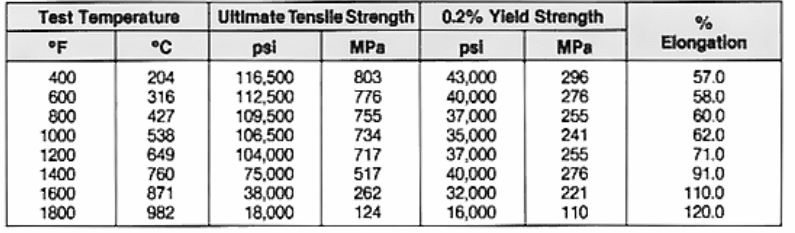

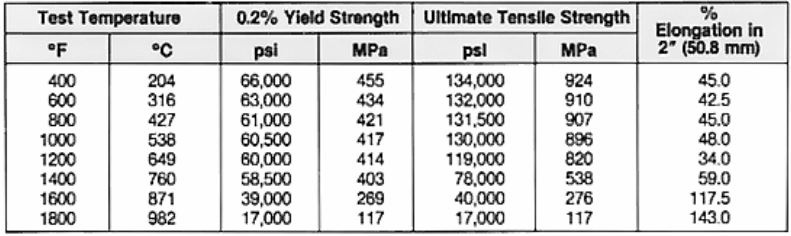

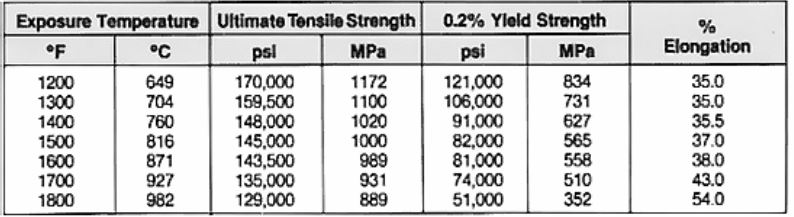

Ngwongwo ike na elu okpomọkụ

Mmetụta nke annealing okpomọkụ

Ngwongwo ike na elu okpomọkụ

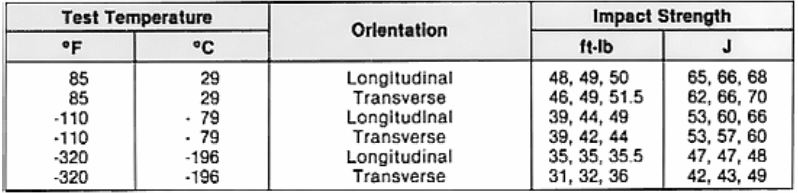

Mmetụta ule-keyhole notch

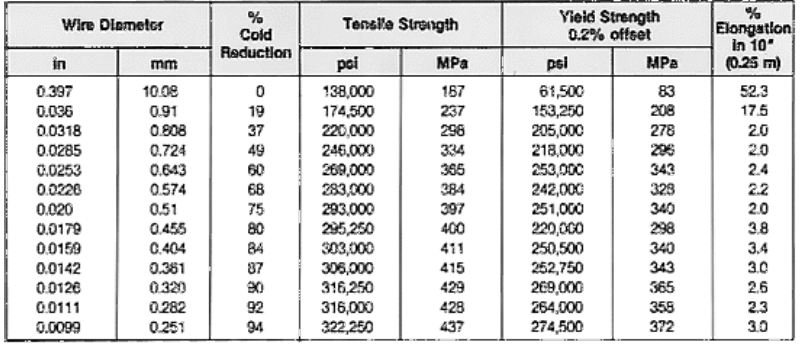

Ngwongwo na-egbu egbu na ime ụlọ

Ike ọdụdọ na ụlọ okpomọkụ

Hot Rolling, ala ngwọta annealing, 100 awa na okpomọkụ depụtara na tebụl n'okpuru

N'usoro doo ike ọgwụgwụ ike ọgwụgwụ

okpomọkụ omume

E nwere ụzọ usoro ọgwụgwọ atọ dị mkpa maka alloy 625:

1. Annealing dị elu: 1093-1204 Celsius C, ikuku ikuku ma ọ bụ ngwa ngwa ngwa ngwa

2. Ntughari ihe ngwọta dị ala: 927-1038 ° C, ikuku ikuku ma ọ bụ ngwa ngwa ngwa ngwa

3. Nchegbu nrụgide: 899 Celsius C, ikuku quenching

Oge ọgwụgwọ okpomọkụ na-adabere na ọnụ ọgụgụ nke ihe na ọkpụrụkpụ nke akụkụ obe. Oge ọgwụgwọ ọkụ nke usoro 1 na 2 na-abụkarị 1 / 2-1 awa, na oge ọgwụgwọ ọkụ nke usoro 3 bụ 1-4 awa.

Mgbe okpomọkụ na-arụ ọrụ dị elu karịa 816 Celsius C na nguzogide creep dị mkpa karị, Usoro 1 na-ejikarị edozi ihe. Igwe igwe ga-ejikwa ihe ngwọta dị elu na-eme ka ihe ahụ dị nro ma dị mfe iji mpịakọta oyi ma ọ bụ ihe osise.

Usoro 2 bụ usoro ọgwụgwọ ọgwụgwọ a na-ejikarị eme ihe. 1038 ° C nwere ike na-ebuli arụmọrụ zuru oke nke ike mgbagha na ike ịgbawa. N'otu oge, ductility na ike n'okpuru ala okpomọkụ gburugburu ebe obibi dịkwa ezigbo mma.

Mgbe okpomọkụ ọrụ na-arụ ọrụ dị n'okpuru 649 Celsius C, mgbe ihe ndị achọrọ na nkwụsi ike ike, ike mgbagha, ike mkpụrụ na ike nke ihe a dị elu, Usoro 3 ka akwadoro maka ọgwụgwọ okpomọkụ. The mesoo ihe nwere nnọọ mma ductility na ike na ala okpomọkụ gburugburu ebe obibi. Ọ bụrụ na achọrọ oke ọka, ihe a ga-enwe ezigbo ike ọgwụgwụ, ike mgbagha na ịmị mkpụrụ na gburugburu 816 Celsius C. Oge ụfọdụ enwere ike iji 3 mee ihe.

Usoro nhazi

Oke ọkụ ọkụ maka nhazi ọkụ bụ 1149 Celsius C. Lezie anya iji zere nchịkọta nke ọkụ ọkụ nke nwere ike ime ka ikpo oke ọkụ gafee 1149 Celsius C. Alloy 625 ga-adịwanye ike n'okpuru 1010 Celsius C. Ọ bụrụ na ọ dị n'okpuru okpomọkụ a, workpiece kwesịrị reheated. Ọ na-atụ aro ya ịrụ ibe ibe ya iji zere mbuaha kristal Ọdịdị. Onu ogugu ghachara banyere 15-20%.

Nzuzo Nhazi

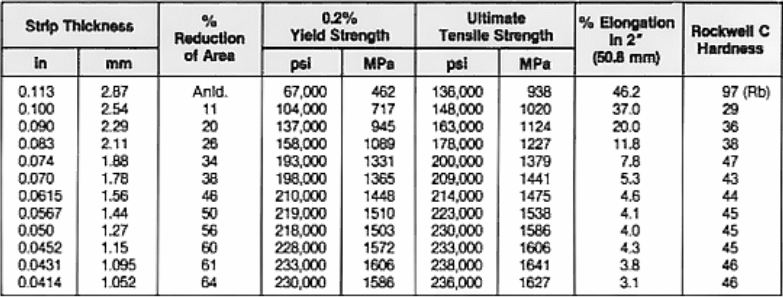

625 alloy adabara a dịgasị iche iche nke ọkọlọtọ oyi na-arụ ọrụ ụzọ. Mgbe ọrụ oyi na-arụ, ihe nrụpụta ahụ na-agbanwe agbanwe ma nwee ike weghachite ya na ọrụ ya site na mgbakwunye.

Mmetụta nke ọrụ oyi

Tupu oyi na-arụ ọrụ, a na-etinye eriri ahụ na 1019 Celsius C

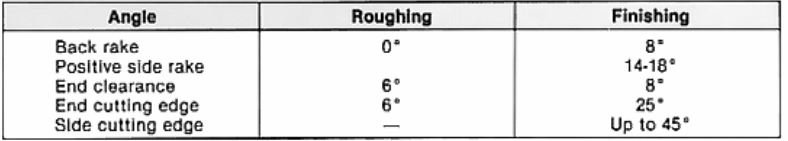

Ọrụ igwe

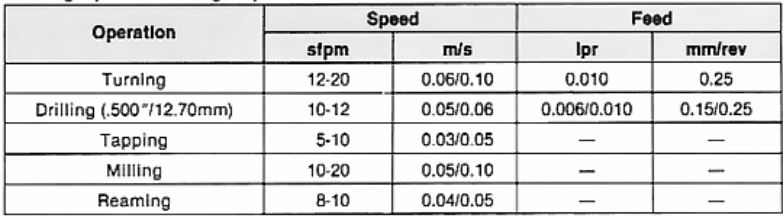

A na-atụkarị aro ka ị jiri obere ọsọ ọsọ, akụrụngwa dị egwu, akụrụngwa dị arọ, igwe zuru ezu, na nri mmanye iji hazie alloy 625.

Ntughari nke ngwa ngwa ngwa ngwa

Oke ọkụ ọkụ maka nhazi ọkụ bụ 1149 Celsius C. Lezie anya iji zere nchịkọta nke ọkụ ọkụ nke nwere ike ime ka ikpo oke ọkụ gafee 1149 Celsius C. Alloy 625 ga-adịwanye ike n'okpuru 1010 Celsius C. Ọ bụrụ na ọ dị n'okpuru okpomọkụ a, workpiece kwesịrị reheated. Ọ na-atụ aro ya ịrụ ibe ibe ya iji zere mbuaha kristal Ọdịdị. Onu ogugu ghachara banyere 15-20%.

Oke-ọsọ ígwè ọnwụ ọsọ

Uzo nke carbide bu ihe pere mpe karie nke ngwa HSS, ya na igbutu ya karia.

A na-atụ aro ka ị jiri sọlfọ na-egbu mmiri. Mgbe emechara ya, ọ dị mkpa iji dozie ihe eji arụ ọrụ iji zere iweta ihe ndị na-emerụ emerụ n'ime usoro ọgwụgwọ ọkụ na-esote.

ịgbado ọkụ

A pụrụ iji ịgbado ọkụ gas maka ịgbado ọkụ, tungsten electrode ma ọ bụ electrode na-ere ere. Ọ dịghị post-Weld okpomọkụ ọgwụgwọ achọrọ iji nọgide na-enwe corrosion eguzogide. Tupu ịgbado ọkụ, attentionaa ntị iji kpochapụ ebe a na-ekpo ọkụ ma dozie oghere ịgbado ọkụ. Oke nkpuchi ọkụ na-agbaso usoro ịgbado ọkụ U.

Njikọ na akụkọ a : Kedu ihe na-enweghị isi 625

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

Lọ ahịa PTJ CNC na-arụpụta akụkụ nwere ezigbo ihe eji arụ ọrụ, izi ezi na nrụpụta site na igwe na plastik. 5 axis CNC egwe ọka dị.Igwe na-edozi alloy dị elu iche iche mkpu igwe ihe ndozi,Nkwanye monel,Igwe ihe omimi nke Geek,Carp 49 igwe,Ngwaọrụ Hastelloy,Ngwunye nitronic-60,Ndinam Hymu 80,Ngwá ọrụ ígwè machining, wdg. Ezigbo maka ngwa aerospace.CNC igwe na-arụpụta akụkụ ya na ezigbo ngwa ọrụ ya, izi ezi ya na ike ya site na igwe na plastik. 3-axis & 5-axis CNC milling available.We ga strategize na ị na-enye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị lekwasịrị anya, Welcome to Kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

Lọ ahịa PTJ CNC na-arụpụta akụkụ nwere ezigbo ihe eji arụ ọrụ, izi ezi na nrụpụta site na igwe na plastik. 5 axis CNC egwe ọka dị.Igwe na-edozi alloy dị elu iche iche mkpu igwe ihe ndozi,Nkwanye monel,Igwe ihe omimi nke Geek,Carp 49 igwe,Ngwaọrụ Hastelloy,Ngwunye nitronic-60,Ndinam Hymu 80,Ngwá ọrụ ígwè machining, wdg. Ezigbo maka ngwa aerospace.CNC igwe na-arụpụta akụkụ ya na ezigbo ngwa ọrụ ya, izi ezi ya na ike ya site na igwe na plastik. 3-axis & 5-axis CNC milling available.We ga strategize na ị na-enye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị lekwasịrị anya, Welcome to Kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo