Kedu ihe kpatara iji 718 arụ ọrụ iji rụpụta akụkụ ụgbọ elu

Kedu ihe kpatara iji 718 arụ ọrụ iji rụpụta akụkụ ụgbọ elu

|

Ogologo oge gara aga, ndị mmadụ malitere iji usoro broaching ịhazi ire na uzo na diski turbine gas. A na-edozi agụba ahụ na diski turbine site na ire na uzo. Otú ọ dị, broaching ga-eme mgbanwe na nhazi nke elu na akwa dị n'okpuru diski tobaim, nke ga-emetụta nguzogide ike ọgwụgwụ nke wiil ahụ. |

Ya mere, na njikarịcha njikarịcha nke usoro broaching, ọ dị ezigbo mkpa ịbịaru eserese a na-atụkwasị obi na nke a na-atụzi nke tenon groove nke broaching. N'isiokwu a, anyị ejirila igwe onyonyo nyocha na nyocha microscopy iji nyochaa usoro metallographic nke elu na ala ala nke teno grooves nke Inconel-718 alloy disk of gas gas turbines. Ihe a na-elekwasị anya bụ n'ịmụ njirimara nke ntụpọ ndị na-eme site na ị na-ebugharị tenons na grooves n'elu na n'okpuru wiwi ahụ. N'otu oge ahụ, nyocha ahụ chọkwara nha nke akụrụngwa γ ", γ 'na δ n'elu ire na uzo. Ọ dị mkpa iji tinye usoro njirimara njirimara ndị a nke usoro ihe ntụzịaka ahụ. N'ihe banyere usoro nhazi, anyị chọpụtara ntụpọ dị ka ọkọ na agbagọ. Ndị na-emepụta turbine gas ahụ Na mgbakwunye, mpaghara ndị metụtara broaching na Ntụle nke ihe ndị mbụ ahụ na-egosi na ọnụọgụ nke mkpụrụ ọka nwere mgbanwe doro anya. Akụrụngwa, anyị atụlego microstructure ekweghị ekwe evolutionation nke metallurgical Ọdịdị na broaching elu.

Inconel-718 alloy bụ alloy Ni-Fe-Cr nke dị elu nke International Nickel Corporation mepụtara na 1950s. Nke a bụ ihe mmiri ozuzo na-eme ka mmiri sie ike nke nwere ike igosi nrụgide dị elu na iguzogide ike ọgwụgwụ na nkụ. N'ihi nnukwu nguzogide oxidation ya na ike dị elu na gburugburu okpomọkụ dị elu, a na-ejikarị Inconel-718 alloy eme ihe na ụlọ ọrụ aerospace, ọkachasị dị ka ihe eji arụ ọrụ igwe. N'ikwu okwu n'ozuzu, wiil na agụba ahụ jikọtara ọnụ site na ogologo osisi nke nwere ogologo osisi, usoro bro bro bụ isi ihe na-arụ ọrụ ịkpụzi ogologo akụkụ nke ogologo osisi. Na mkpokọta, nchegbu onye ọ bụla bụ mmetụta nke ọnọdụ okpomọkụ na esemokwu na mgbanwe nha ọka n'oge nrụrụ ọkụ. Broaching ga-emekwa ka mgbanwe na metallographic Ọdịdị nke elu na-akpata elu nke wheel, nke ga-emetụta ike ọgwụgwụ nke wheel. Agbanyeghị, na akwụkwọ, enwere akwụkwọ ole na ole na broaching nke Inconel-718 alloy wheels Qualitative na quantitative analysis of microstructure.

Ebumnuche nke ọmụmụ a bụ ịkọwa na ịkọwapụta ọdịdị nke metallographic nke elu na ihe ndabere nke ogologo dendritic ditritic nke wheel Inconel-718. Karịsịa, e dekọtara nkọwa na nchịkọta nke ntụpọ nke usoro broaching n'elu na ala ala nke diski wiil ahụ, a na-amụrụ oke ọka na njirimara ọka nke mpaghara igwe ahụ.

Usoro nyocha

Anyị weghaara akụkụ nke wiilị Inconel-718 alloy maka nyocha (Nyocha 1). Dika egosiputara na onu ogugu 2, anyi n’eji usoro nke EDM were ihe nlere site na nke mbu, etiti na odu nke etiti tenon slot.

Iji gboo mkpa nke nyocha nke metallographic, mgbe emechara ihe nlele ahụ, ọ ga-agafe na usoro akpaghị aka nke egweri na nchacha. Mgbe sanding, a ga-eji sandpaper 320, 400, 600 na 1200 mee ihe. Mgbe polishing, nke sample ga-egbu maramara na MD ajị anụ na 1 diamondm diamond nkwusioru dị ka polishing mmiri mmiri maka 2 nkeji. Iji nwee ike iji aka nyochaa micronpe (SEM), mkpụrụ osisi ahụ ga-agbakwunye na azịza nke oxalic acid na voltage nke 4V maka 20-40 sekọnd. Iji weghara njirimara nke γ 'na γ' na nkọwa dị elu, achọrọ ka ihe atụ ahụ bụrụ ihe galvanic etinyere na voltage 10V (8ml H2SO4 na 100ml H2O) maka sekọnd 20, yana igwe onyogọn elektrọnik nke nwere onyonyo ọkụ na-agbapụta. (FEG).

Mgbe ị na-enyocha ntụpọ na SEM, achọrọ ka etinyere ya na voltage 3V (5g CuCl2, 100ml HCL na 100ml ethanol) maka 10 sekọnd. Jiri usoro dị iche dị elu iji nweta oke ọka. Jiri ASTM iji nweta oke mpịakọta nke ọka dị iche iche: E562 na-eche na akụkụ mpaghara ahụ hà nha akụkụ dị nta. Ogologo ọka dị iche iche ka ejiri ihe nyocha ihe onyonyo Clemex tụrụ. Iji nweta nsonaazụ ọnụ ọgụgụ nke onye nnọchianya, ọ dịkarịa ala, a ga-eji ihe osise metallographic 6 mee ihe iji chọpụta nha na njirimara nke ọka dị iche iche.

Ọ dịkarịa ala, ihe atụ 5 nke ihe nlele ọ bụla ka a ga-ewere maka Rockwell A siri ike, ma mgbe ahụ, a ga-agbakọ uru ọnụahịa maka ihe nlele ọ bụla. Na nyocha, ebe dị anya n'etiti ọkọlọtọ na-adịkarị karịa 5 ugboro dayameta nke ọkọ. Iji jiri ya tụnyere ịdị ike nke ụkpụrụ akwụkwọ, Rockwell A hardness ụkpụrụ kwesịrị ka a gbanwee ya na Vickers hardness, ASTM: E140.

Nyocha Ezughị oke

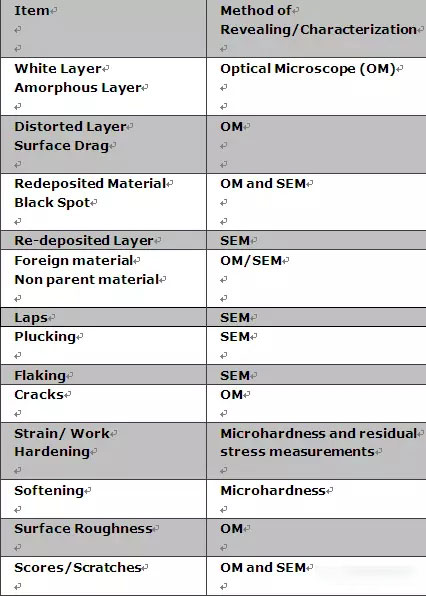

N'ime ọmụmụ ihe a, anyị tụlere ntụpọ n'ahịrị na etiti. Kpọmkwem, anyị hụrụ ma kwupụta mbido, etiti na ngwụcha nke broaching. Isiokwu 1 na-egosi ụdị ntụpọ dị iche iche gụnyere na ogologo dendritic grooves nke broched Inconel-718 alloy wheached. Ekwesiri ikwuputa na n'ime nyocha nyocha, anyị ahụghị ntụpọ dị ka akwa ọcha, akwa oyi akwa, usoro nke abụọ, ntụpọ ojii, ntinyeghachi, okwu mba ọzọ, na mgbape.

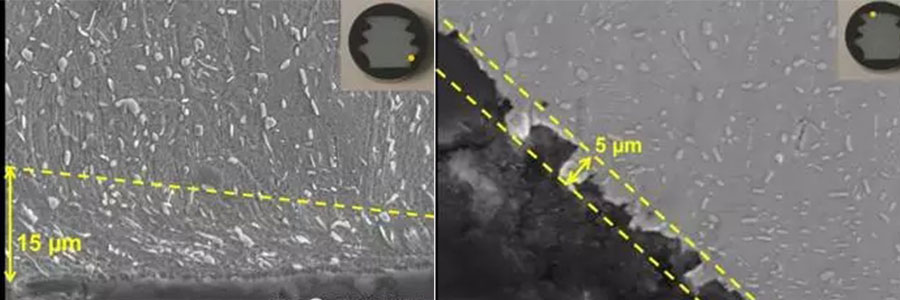

Nọmba 3 ruo 6 na-egosi ụfọdụ ntụpọ achọpụtara. Ihe ngosi 3 na-egosi mbuze, dị ka obere oghere ndị na-egosi na igwe akụrụngwa. N’ezie, ịkọ ọkọ bụ nkwarụ kachasị elu. Onye ọ bụla maara na Inconel-718 alloy siri ike na-arụ ọrụ n'ihi ngwa ngwa ya na-eme ka ọ dị ike n'oge nhazi. Dị iche iche ngwá ọrụ ihe na broaching ọnọdụ, n'elu alloy ga-amụba n'akụkụ eyi, olulu na punching. Agbanyeghị, na nyocha nyocha niile, oke nchara dị ala karịa obere ka emebere. N'otu aka ahụ, dị ka egosiri na ọnụ ọgụgụ 4, a na-egosi ihe oyiyi nke oyi akwa ahụ gbagọrọ agbagọ. Na akwa a (7 μm obosara), δ phase nwere ndokwa pụrụ iche. Ihe omuma a di mfe na elu nke ire na uzo, nke nwere ike ibute nchekasị nke broaching na mpaghara a.

Uzo siri ike nke ire na uzo (ogugu 5) di na nmalite na ngwụcha nke broaching. N'otu aka ahụ, dị ka egosiri na ọnụ ọgụgụ 6, enwere ntụpọ a na-akpọ nkewa ihe ezughi oke, nke yiri mgbaji nke ihe, mana ọ daa na elu wiil ahụ. Ihe omuma a di na ihe omuma nile. Dedị ntụpọ ndị a nwere ogologo 25 μm n'ogologo, njirimara ha (nha na morphology) dị iche. Nkwarụ a sitere na ogo broaching, na mmetụta ya na ndụ nke roulette ka ga-amụkwu.

Njikọ na akụkọ a : Kedu ihe kpatara iji 718 arụ ọrụ iji rụpụta akụkụ ụgbọ elu

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

Lọ ahịa PTJ CNC na-arụpụta akụkụ nwere ezigbo ihe eji arụ ọrụ, izi ezi na nrụpụta site na igwe na plastik. 5 axis CNC egwe ọka dị.Igwe na-edozi alloy dị elu iche iche mkpu igwe ihe ndozi,Nkwanye monel,Igwe ihe omimi nke Geek,Carp 49 igwe,Ngwaọrụ Hastelloy,Ngwunye nitronic-60,Ndinam Hymu 80,Ngwá ọrụ ígwè machining, wdg. Ezigbo maka ngwa aerospace.CNC igwe na-arụpụta akụkụ ya na ezigbo ngwa ọrụ ya, izi ezi ya na ike ya site na igwe na plastik. 3-axis & 5-axis CNC milling available.We ga strategize na ị na-enye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị lekwasịrị anya, Welcome to Kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

Lọ ahịa PTJ CNC na-arụpụta akụkụ nwere ezigbo ihe eji arụ ọrụ, izi ezi na nrụpụta site na igwe na plastik. 5 axis CNC egwe ọka dị.Igwe na-edozi alloy dị elu iche iche mkpu igwe ihe ndozi,Nkwanye monel,Igwe ihe omimi nke Geek,Carp 49 igwe,Ngwaọrụ Hastelloy,Ngwunye nitronic-60,Ndinam Hymu 80,Ngwá ọrụ ígwè machining, wdg. Ezigbo maka ngwa aerospace.CNC igwe na-arụpụta akụkụ ya na ezigbo ngwa ọrụ ya, izi ezi ya na ike ya site na igwe na plastik. 3-axis & 5-axis CNC milling available.We ga strategize na ị na-enye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị lekwasịrị anya, Welcome to Kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo