The Technology iche na machining nke ziri ezi na jikọtara lathes

The Technology Range nke jikọtara Lathes

|

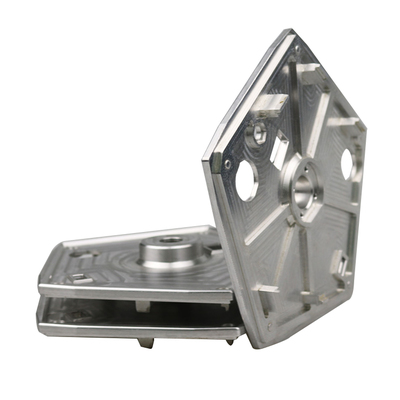

A na - ejikarị lathe a na - ejikọta ihe maka ụdị usoro abụọ: ịkpụzi ụgbọ elu na nhazi oghere. Igwe ụgbọelu na-agụnye ụgbọ elu dị nkọ, nduru (uru) ụgbọ elu, ihu ihu ala ụgbọ ala; |

Oghere machining gụnyere mkpọpu ala, ịgbasa, reaming, oghere mkpọpu ala, chamfering, grooving, na ịme ọpịpị, Ming sinking, Rolling oghere, wdg Na mmepe nke ike akpaaka, ya

Teknụzụ dị na teknụzụ na-agbasa na gburugburu nke ụgbọ ala, igwe 4l na-agagharị, na-agbagharị, na-agbanye, na-egweri, Qi na-egweri na ncha stampụ na usoro ndị ọzọ. Na mgbakwunye, ị nwere ike ịmechaa

Ọrụ na-enweghị mbelata dị ka ịgbado ọkụ, ọgwụgwọ okpomọkụ, mgbakọ na nyocha na akpaka, nhicha na nhazi akụkụ na mbipụta.

Ngwakọta lathes jikọtara ọnụ na ọnụ ọgụgụ dị ukwuu na ụlọ ọrụ ọkụ dị ka ụgbọ ala, igwe tulip, injin mmanụ dizel, injin eletriki, ngwa ọrụ, igwe agha na igwe ịkwa akwa, igwe igwe, wdg.

E jirila ya mee ihe na mmepụta; ụfọdụ ụlọ ọrụ mmepụta obere na ọkara, dị ka akụrụngwa igwe, locomotives, igwe ihe eji arụ ọrụ na ụlọ ọrụ mmepụta ihe ndị ọzọ agbalitela ngwa.

Ngwakọta lathe kachasị mma maka nhazi ụdị igbe igbe dị ukwuu na nke ọkara, dị ka isi isi isi, mkpọchi cylinder, giaigbe ahụ, isi moto na akụrụngwa akụrụngwa, wdg.

Enwekwara ike iji ya iji wuchaa akụkụ ma ọ bụ igwe akụrụngwa nke akụkụ dịka ohias, roulettes, yok na mkpuchi efere.

Machining nke ziri ezi nke jikọtara lathes

1.Hole machining

>1 Akụkụ zuru oke nke oghereMgbe ị na-eji oghere reaming ma ọ bụ oghere gọọmentị, izi ezi nke oghere ndị ahụ nwere ike iru ọkwa H6, na ike adịghị mma bụ Ral. 65m. Oghere nke oghere ndị ahụ dị n'etiti ọkara nke ndidi nke oghere oghere. Mgbe ị na-akpụzi ọla ndị na-abụghị ígwè. Iji nkenke ndozi. Mgbe 3-4 machining, nkenke nwere ike iru H6 larịị na elu ike ike iru RaO. 8 ^ -RaO. 45m

>2 Ọdịdị nke oghere ahụ

05mm。 Mgbe ị na-arụ ọrụ site n'akụkụ abụọ multi-axis. Coaxiality nke oghere bụ n'ozuzu 0. 05mm. Mgbe ị na-eme ezigbo oghere site n'otu akụkụ, ma jiri ndozi edozi, enwere ntuzi ziri ezi na nsọtụ abụọ nke ogwe ngwaọrụ. N'okpuru ọnọdụ nke ezi ziri ezi, njikota ahụ dị n'ime 1000mm n'ogologo. 03mm。 Coaxiality nke ọtụtụ oghere nke akụkụ ndị esichara ike-ekwe nkwa n'ime 0. 015 ^ -0. 03mm. Mgbe ị na-arụ ọrụ uniaxial site na oghere ndị dị na otu axis n'akụkụ abụọ ahụ, a ga-ekwe nkwa coaxiality n'okpuru ọnọdụ nhazi usoro nhazi. .015-0. 03mm,

>3 Aghota nke oghere

Machining na jikọtara igwe ngwá ọrụ. Ihe omuma di n'etiti oghere na oghere na ihe yiri nke machining base elu mgbe oghere di. Na 1000mm ogologo

Ihe ruru 0.02 ^ -0.05mm,

>4 Ọnọdụ nke oghere

Ọnọdụ nke oghere ahụ nwere mmekọrịta dị ukwuu na ihe ndozi, ụdị igwe na izi ezi. 025-0. 05mm。 Na akụrụngwa akụrụngwa nke ihe ndozi ahụ, oghere ahụ, ebe dị n'etiti oghere ndị ahụ na ọnọdụ nke axis nke oghere ahụ na ebe mgbakwasị ụkwụ nwere ike ịtọ nke ọma na 0. 025-0. 05mm. On multi-ojii igwe ngwaọrụ, n'ihi na n'ọnọdu njehie nke rotary table ma ọ bụ rotary drum, na machining ziri ezi adịghị elu. 05mm。 Ọ bụrụ n'otu ebe ahụ. Mgbe oghere na nghọta ibughari atụrụ nke gwụchara, ọnọdụ ya ziri ezi nwere ike iru 0 05. 0.1mm. Mgbe ị na-arụ ọrụ oghere dị iche iche na ọdụ dị iche iche, izi ezi dị ala. Mgbe ị na-eji akụrụngwa na-arụ ọrụ na-arụ ọrụ na-arụ ọrụ na-arụ ọrụ na tebụl, ihe ziri ezi nwere ike iru 0 2mm. Mgbe ị na-eji igwe eji arụ ọrụ igwe eji arụ ọrụ. Izi ezi ya nwere ike iru ± 0. 2mm. Ọbụna ala. Mgbe egwu na otu ebe, ọnọdụ ziri ezi bụ n'ozuzu n'ime ± 15. 0mm. 15mm. Mgbe ị na-egwupu ihe akụrụngwa igwe na ihe eji egwu mmiri edozi, izi ezi ya nwere ike iru ± XNUMX. XNUMXmm.

>5 Vetikal nke oghere

02mm. Maka ịkwanye oghere na igwe nchikota, etiti dị n'etiti nwere ike ịdị n'akụkụ elu ala yana n'akụkụ etiti nke oghere ọzọ ka ọ dị iche nke 0. 02mm n'ime ogologo nke 100mm.

>6 Eriri oghere ziri ezi

A na-ejikarị oghere ndị a na-ejikọ na igwe igwe jikọtara ọnụ maka ịkụ na ịnwụ. Ọ bụrụ na ọnọdụ mmanu dị mma, a ga-edozi oghere ndị nwere nkenke 7 na nkedo ígwè. Ihe ihu igwe bụ Ral. 65m,

Izi ezi nke eriri eri na-adabere na oghere ala ya mgbe ọ na-akụ. Site na mmetụta nke njehie ndị ọzọ, ọ dị ntakịrị ala karịa obere mmiri a gbapuru. Ọ nwere ike n'ozuzu iru ± 0. 25mm. Mgbe akụrụngwa akụrụngwa dị elu karịa, enwere ike ịnweta ya Taksi 0. 15mmo

2.Plane igwe

Na ngwa igwe ejikọtara ya na eriri akpaka ya. A na-ejikarị egwe ọka 41. * 1 41, na-atụgharị ma na-adọta 411 na ụzọ ndị ọzọ iji rụọ ụgbọelu ahụ. Igwe na-ejikarị igwe na-egbusi ihe, tebụl slide, oche slide na ihe ndị ọzọ n'ozuzu. Dị ka usoro chọrọ nke workpiece na-esichara, ọ na-etolite otu-kwadoro, abụọ-kwadoro, vetikal, rotary table na ndị ọzọ ụdị nke jikọtara igwe igwe. Mgbe ị na-arụ ụdị ihe eji arụ ụdị igbe dị ukwuu, ụdị nhazi nke a na-edozi isi mbepụ isi ya ma tinye ya na mpempe akwụkwọ na-arụ ọrụ na tebụl ọrụ. Ngwa akụrụngwa dị otú ahụ nwere usoro dị mfe, nkwụsi ike dị mma, na oke nkenke igwe. Mgbe ị na-arụ ọrụ obere na ọkara dị larịị, a na-ejikọ igwe igwe 411 ka ọ bụrụ igwe igwe na-agwakọta igwe ma ọ bụ igwe na-aga n'ihu na-aga n'ihu. Typedị igwe ọrụ a nwere arụmọrụ dị elu yana arụmọrụ ziri ezi dị ala.

Flatness nke machining ụgbọelu na jikọtara igwe ngwá nwere ike iru a ndiiche nke 0.02-0.05mm n'ime a ogologo nke 1000mm. Igwe ihu ala bụ Ra3.25m. Enwere ike ijikọta ihe njikọ nke ntọala ntọala. N'ime .05mm. Ogologo nke isi ntọala nwere ike ịbụ nha ihu

Ekwere nkwa n'ime 0. 05mm.

3.Ọgwụgwụ ngwụcha

Multi-axis machining. Usoro nke iji slide ike iji nọrọ na gia ndị nwụrụ anwụ. 25mm, ya machining ziri ezi nwere ike iru 0. 15 ^ -0. 25mm. Ngwaọrụ Uniaxial. A na-eji usoro pụrụ iche arụ ọrụ. Ọgwụgwụ nke machining na-eme ka elu nke ndị nwụrụ anwụ gia n'elu workpiece na-hazie, na izugbe ziri ezi nwere ike iru 0. 08-0. 10mm. Mgbe onodu di nma. Ezi ga-ekwe nkwa. . 02-0. N'ime 045mm.

Njikọ na akụkọ a : The Technology iche na machining nke ziri ezi na jikọtara lathes

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ Na-enye ihe ngosipụta, mmepụta zuru ezu na-agba ọsọ, nkwado teknụzụ na nyocha zuru ezu akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ Na-enye ihe ngosipụta, mmepụta zuru ezu na-agba ọsọ, nkwado teknụzụ na nyocha zuru ezu akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo