Oru oma machining nke Titanium Alloy Aircraft Parts

Oru oma machining nke Titanium Alloy Aircraft Parts

|

Ngwongwo Titanium nwere uru nke njuputa di ala na nguzogide corrosion, ma jiri ya na aru nke ugbo elu ugbo elu, mana o na-adighi nma na nbibi n'oge igwe cnc, na ichikota uzo di ike ikwenye. Ya mere, ọ dị mkpa iji teknụzụ ọgbara ọhụrụ na akụrụngwa zuru oke iji mepụta usoro ọfụma dị mma, yana meziwanye arụmọrụ na arụmọrụ zuru oke. CNC igwe akụrụngwa. Nyocha miri emi jikọtara ya na titanium ihe nkedo alloy A na-eji usoro emeziwanye arụmọrụ nke akụkụ ndị metụtara ya |

Dị ka a ụdị nke elu-ike ihe onwunwe akụkụ, titanium alloy akụkụ nwere kemgwucha elu ngwa uru na akụkụ ụgbọ elu ubi. Usoro nhazi nke ọdịnala anaghịzi adabara maka mmepụta nke usoro ụgbọ elu nke oge a. Ya mere, iji akụkụ nke titanium alloy nwere ike izute ihe ndị chọrọ maka mmepe ụgbọ elu ruo n'ókè kachasị. Ejiri ọtụtụ akụkụ titanium alloy na-arụ ụgbọ elu. Dịka ọmụmaatụ, enwere ike iji kposara na mkpụrụ dozie okpokoro agbaji, yana akụkụ dị mkpa dị ka njin ihu igwe na ọdịda gia nwere ike nke titanium alloy ihe.

Ugbo ngwa na uru nke akụkụ alloy titanium

1.1 Titanium alloy akụkụ ngwa ubi

Were ụgbọ elu ndị njem B777 dị ka ihe atụ. A na-eji nkedo alloy titanium eme ihe maka imepụta ụgbọ elu ụgbọ elu. Enwere ike ịhụ na n'ichepụta ụgbọ elu obodo, teknụzụ ngwa nke akụkụ titanium alloy abụrụla nke tozuru etozu. Tụkwasị na nke ahụ, akụkụ alloy titanium dịkwa nnukwu mkpa maka mmepe ụlọ ọrụ ụgbọelu. Dịka ọmụmaatụ, ụlọ ọrụ European Doncasters na-eji teknụzụ nkedo centrifugal iji tinye titanium alloy na torque torke.

1.2 ngwa uru nke titanium alloy akụkụ

Titanium alloy akụkụ nwere uru ndị a:

- Nke mbụ, ọ dịghị mkpa iji ihe ọkpụkpọ n'oge usoro ịkpụzi;

- Nke abuo, odighi mkpa itinye otutu ume na ego na ogbo nkwadebe nke mbu;

- Nke ato, ọ nwere ike n'ụzọ dị irè melite arụmọrụ nke ihe onwunwe ojiji. Titanium alloy akụkụ ọ bụghị naanị melite arụmọrụ nchekwa nke ihe eji arụ ọrụ ụgbọ elu, kamakwa belata ọnụọgụ nke akụkụ ejikọtara, na-echekwa oge nzukọ ntuziaka, ma na-enweta nsonaazụ nke ụzọ ụzọ abụọ nke ego na mma.

Njirimara nke ugbo elu titanium alloy

2.1 adịghị mfe deform

Titanium alloy ihe nwere ike dị elu na ike okpomọkụ, ma nwee obere njupụta. E jiri ya tụnyere ihe nchara, ọ bụ naanị 60% nke njupụta nke nchara. Nke a na-eme titanium alloy ihe enweghị nsogbu nrụrụ ọbụlagodi na oke okpomọkụ nke 300 Celsius C ruo 500 Celsius C. Ngwurugwu titanium alloy nke ụdị engine ụgbọelu na-arụ ọrụ site na TC4 titanium alloy na-arụ ọrụs Ubu ya bụ 19.987kg, obosara ya bụ 600mm, na ogologo ya bụ 2800mm, ma mgbidi mgbidi bụ naanị 1.50mm.

2.2 obere okpomọkụ na-eguzogide

Ngwongwo titanium nwere nguzogide di elu di elu, ya bu, o ka nwere ike idozi ya nke oma n’okpuru ihe onodu oku di ala ma obu ala. Ọ bụ ihe nwere ike iguzogide okpomọkụ dị ala. Dịka ule ndị metụtara ya, a maara na titanium alloy dị na -196 ° C. N'okpuru ebe a, ike ọdụdọ σb bụ 1207Pa.

2.3 ike corrosion eguzogide

Titanium alloy akụkụ nwere ike ọtụtụ-eji na ugbo elu ubi, a dị ezigbo mkpa ihe kpatara ya bụ na ọ nwere ibu corrosion eguzogide. Mgbe ụgbọ elu na-efe elu, ihe ndị dị na ikuku ga-enwe mmetụta na-emebi emebi n'elu ụgbọelu ahụ. Titanium alloy akụkụ nwere ike ịnagide nsogbu a wee hụ nchekwa nke ụgbọ elu ahụ.

2.4 Na njirimara kemịkal

Ngwongwo titanium nwere ike imeghachi ihe di iche iche nke igwe. Site n'enyemaka nke mmeghachi omume kemịkal, a ga-eme ka akụrụngwa nke titanium dị elu. Dịka ọmụmaatụ, na gburugburu ebe dị elu dị elu karịa 600 Celsius C, alloy titanium nwere ike imeghachi omume na oxygen iji mepụta oyi akwa oxide kwekọrọ.

2.5 obere nrụpụta ọkụ

Ntinye nke ihe di iche iche nke titanium na ugbo elu nwere ike belata ihe puru omume nke odida nke akuku ugbo elu, ma zere oke ikpo oku nke ugbo elu nke na emetuta ihe ndi ozo.

2.6 Obere ihe eji eme ya

N'ime usoro iji akụkụ alloy titanium, etinyela ha n'ime akụkụ gị dị gịrịgịrị. Nke a bụ n'ihi na ụdị mgbanwe nke titanium alloy dị obere ma ọ dị mfe nrụrụ. Na mgbakwunye, na titanium igwe usoro, n'ihi nnukwu rebound nke titanium alloy, ọ dị mfe iyi ngwá ọrụ ahụ.

Ngwuputa Ngwa na Ngwa Ngwa nke Titanium Alloy Parts

Alọ ọrụ ụgbọelu nke China na-etinye oke mkpa na ngwa nke akụrụngwa, na R & D na-elekwasị anya na mmepe usoro na ngwa iji melite arụmọrụ nke ụgbọ elu.

3.1 Imebisie ubi nke titanium alloy oge ọgbụgba

Tụnyere ndị ọzọ akụkụ titanium, ulo oru mbo mgbatị usoro nwere ya pụrụ iche uru:

- Nkedo size ziri ezi, elu bụ dịtụ ezigbo, na ike ike bụ ala;

- Ọ nwere ike ịtụ ihe nkedo ndị nwere mgbagwoju anya;

- Mgbe ị na-emeziwanye ihe eji eme ihe nke ihe eji eme ihe, ọ nwekwara ike melite mgbanwe na mmegharị.

Agbanyeghị, n'ime usoro ntinye ngwa ngwa, ike nke alloy titanium enweghị ike mezuo ihe achọrọ iji wuo ụgbọ elu. Ya mere, ekwesiri itinye mesiri ike na ike nke ike nke titanium alloys n'oge nyocha na mmepe. The mmepe ọsọ nke titanium alloy nkenke mgbatị technology na mba m na-nọgidere na-amụba na-adịbeghị anya. Na ndabere nke a, a na - ejikarị eriri ejiri mpempe akwụkwọ na - arụ ọrụ ụgbọelu. N'ihi oke ihe chọrọ nke ụgbọ elu maka akụkụ titanium alloy, ọnụego e guzobere akụkụ ụgbọ elu titanium nke ala m dị obere. Ya mere, a ga-eji sayensị na teknụzụ mee ihe iji meziwanye ọkwa nkedo, belata ụgwọ mmepụta ngwaahịa na usoro mmepụta ihe, ma nweta ebumnuche imepụta oke. .

3.2 Belata ego mmepe

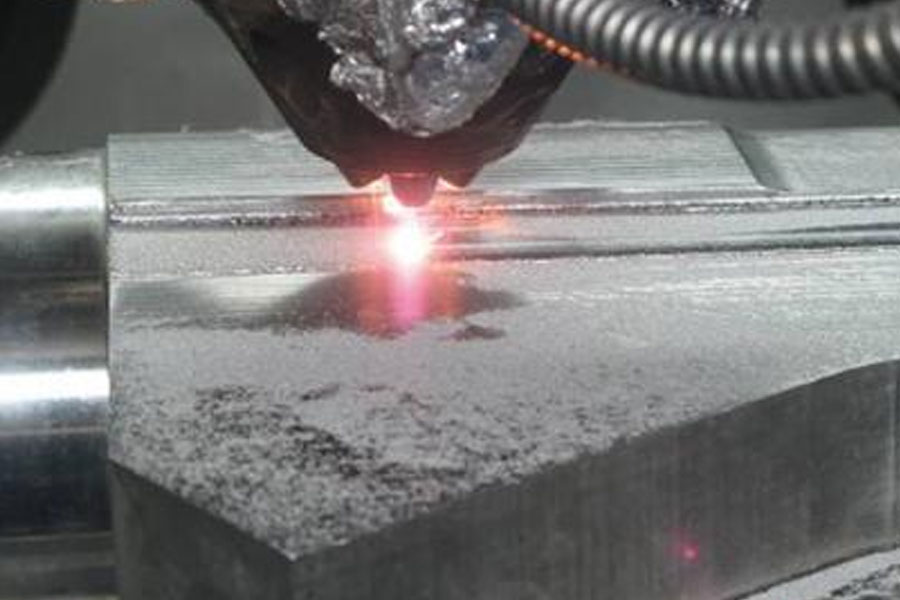

Na ndabere nke elu-ike laser cladding na ngwangwa prototyping, titanium alloy powder laser akpụ technology e ọtụtụ-eji. Nkà na ụzụ a na-eji ụdọ laser dị elu iji gbazee titanium alloy ntụ ntụ ma mee ka ọ sie ike na mkpụrụ nke obere ụmụ irighiri mmiri, wee dabere na teknụzụ njikwa kọmputa iji mee ka isi laser na-agagharị ugboro ugboro, si otú a na-etinye oyi akwa site na oyi akwa, na n'ikpeazụ nweta ihe achọrọ titanium alloy akụkụ.

Ka ọ dị ugbu a, arụmọrụ zuru oke nke titanium alloy bekee emeziwanyela nke ọma, ma belata akụkụ nke akụkụ ya n'onwe ya belatara nke ukwuu, nke ihe ụgbọ elu ahụ kwadoro. Na njikọta na ọnọdụ ahụ n'ezie, ụgwọ Nb, Mo na ihe V dị na alloys titanium dị oke ọnụ, na-eduga n ’ọnụ ahịa akụrụngwa dị elu.

Ya mere, alloys titanium alloys nwere obere ego itinye ego dọtara nnukwu uche. Ka ọ dị ugbu a, ndị nyocha achọpụtala na enwere ike iji ihe Fe iji dochie ọnụ ahịa Nb, Mo na V, nke na - enweghị ike ịhụ na arụmọrụ nke ihe, kamakwa belata nke ọma Ihe ntinye nke titanium alloy raw materials.

3.3 Usoro nkesa na nchedo elu

Na nyocha nke oyi akwa nke BT3-1 na OT4-1, enwere ike ikwubi na nkesa hydrogen na oyi akwa dị mgbagwoju anya, na hydrogen ọdịnaya ga-eji nwayọọ nwayọọ na-abawanye, na mgbe ọ ruru oke kachasị, ọ ga-ebelata ya. Ugbu a, laser atọ akụkụ akpụ technology na titanium alloy akụkụ e irè jikọtara, na nnukwu-ọnụ ọgụgụ titanium alloy isi amị akụrụngwa maka ụgbọ elu.

3.4 Meziwanye ihe eji eme ihe eji eme ihe na - anwu

Mostzọ kachasị dị irè iji mee ka ihe jiri ígwè mee ihe bụ iji obere oxidation na-enweghị kpo oku. Maka ngwongwo titanium, ikpo oku na ikuku ikuku nwere ike idozi nsogbu a nke ọma. Dabere na nyocha yiri ya, mgbe ị na-ekpo ọkụ na ọkụ ọkụ eletrik, ekwesịrị ịchịkwa ọnọdụ okpomọkụ na 950 ℃ ~ 980 ℃. Tụkwasị na nke ahụ, site na ịlele nyocha na BT20 na OT4-1 (TC1), na-ekpo ọkụ ihe atụ niile ma na-anwụ anwụ na-arụ otu, enwere ike ịchọta na ihu ala dị ala na-adịkarị na-egosipụta ezigbo mmetụta, nke na-eduga na ikwubi na oyi akwa oxide na gas saturation steeti nwere mmetụta dị mkpa na ihe ndị na-arụ ọrụ igwe.

mmechi

N'ihe banyere mmepe nke sayensị na teknụzụ na-aga n'ihu, ọtụtụ ụlọ ọrụ emechaala mgbanwe ha, ụlọ ọrụ aluminom nke mba m enwetakwa ezigbo nsonaazụ. N'ime usoro mmepe akụ na ụba ngwa ngwa, ụlọ ọrụ titanium alloy na-aga n'ihu na-etolite na nduzi nke ume ọhụrụ, na-enyere akụkụ titanium alloy aka iji rụọ ọrụ nke ọma n'ọtụtụ mpaghara, na-atọ ntọala siri ike maka mmepe nke nchekwa ọkụ na mbelata nsị.

Njikọ na akụkọ a : Oru oma machining nke Titanium Alloy Aircraft Parts

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwangwa nkenke ọrụ ndị ọrụ CNC gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined parts with +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwangwa nkenke ọrụ ndị ọrụ CNC gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined parts with +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo