Teknụzụ Ọgwụ Elu nke Aluminom Alloy

Teknụzụ Ọgwụ Elu nke Aluminom Alloy

|

Aluminom nwere ọtụtụ uru dị ka njupụta dị ala, ike dị elu dị elu, ezigbo nguzogide corrosion, ọkụ eletrik na ọkụ ọkụ, weldability, ezigbo plasticity, nhazi na nhazi dị mfe, na ihe ịchọ mma elu dị mma. A na-eji aluminom dị ọcha mee ihe alloy aluminom site n'ịgbakwụnye ihe ụfọdụ alloying. Aluminom alloy dị mma karịa aluminom dị ọcha. Aluminom nwere mma anụ ahụ na akụrụngwa. N'ihi ọdịdị na-arụsi ọrụ ike nke aluminom, ọ nwere ike ịmepụta ihe nkiri amorphous oxide na ikuku, na-eme ka ọ dịkwuo mma na-eguzogide corrosion na mbara igwe, ma ihe nkiri ahụ dị naanị ihe dị ka 4nm, na nhazi ahụ dị nro, dị nro ma dị nro. Ọkpụkpụ, ike siri ike, nkwụsị na-adịghị mma, na ike arụ ọrụ dị ala, ya mere ọ dị mkpa iji aka kpuchie elu aluminom na ihe nkiri iji nweta nzube nke nchebe. Enwere ike nweta ya site na ọgwụgwọ oxidation, electroplating, na mkpuchi mpụga. |

1 ọgwụgwọ oxidation

Usoro ọgwụgwọ oxidation bụ nke kachasị anodic oxidation, chemical oxidation, na micro-arc oxidation. Xu Lingyun et al. [1] mụọ ihe eji arụ ọrụ na nguzogide corrosion nke A356 aluminum alloy site n'ime atọ dị iche iche n'elu omumes: chemical oxidation, anodization na micro-arc oxidation. Site na teknụzụ SEM, yiri ule na ule nguzogide corrosion, morphology elu, ọkpụrụkpụ oxide, iyi nguzogide na nguzogide corrosion nke alloy aluminum mgbe atọ gasịrị. n'elu omumes e nyochara na tụnyere n'uju. Nsonaazụ gosiri na mgbe dị iche iche n'elu omumes, aluminom alloy elu nwere ike ịmepụta ihe nkiri oxide nke ọkpụrụkpụ dị iche iche, a na-emeziwanye ike nke elu ya na nguzogide iyi, yana nguzogide corrosion nke alloy na-emekwa ka ọ dịkwuo ogo dị iche iche. N'ihe gbasara arụmọrụ n'ozuzu, micro-arc oxidation dị mma karịa oxidation anodic, na anodic oxidation dị mma karịa chemical oxidation.

1.1 Anodizing

A na-akpọkwa anodizing electrolytic oxidation, nke bụ n'ezie ọgwụgwọ oxidation electrochemical. Ọ na-eji aluminom na aluminom alloys dị ka anodes na electrolytic cell, na ihe oxide film (tumadi Al 2 O 3 oyi akwa) na-guzobere na aluminum elu mgbe ike na. Ihe nkiri oxide nwetara site na anodic oxidation nwere ezigbo nguzogide corrosion, usoro kwụsiri ike na nkwalite dị mfe. Ọ bụ usoro ọgwụgwọ elu kachasị na nke a na-ahụkarị maka aluminom na aluminom alloy na obodo m nke oge a. Ihe nkiri oxide nke anodic nwere ọtụtụ njirimara: ihe mgbochi ihe mgbochi nke ihe nkiri oxide nwere ike siri ike, ezigbo ihe mgbochi na-eyi, nkwụsị nke corrosion dị mma, ihe mkpuchi dị mma, nkwụsi ike nke kemịkal dị elu, a pụkwara iji ya mee ihe dị ka ihe nkiri ndabere maka mkpuchi; ihe nkiri oxide nwere ọtụtụ pinholes ma nwee ike iji ya mee ihe na agba dị iche iche iji mee ka ọrụ ịchọ mma nke elu aluminom dịkwuo elu; conductivity thermal conductivity nke ihe nkiri oxide dị oke ala, ọ bụkwa ezigbo mkpuchi ọkụ na oyi akwa na-eguzogide okpomọkụ. Otú ọ dị, ugbu a anodic oxidation nke aluminum na aluminum alloys na-ejikarị chromate dị ka oxidant, nke na-akpata nnukwu mmetọ gburugburu ebe obibi.

Na nyocha nke ugbu a na anodizing nke aluminom na aluminum alloys, a na-akwụkwa nlebara anya na iji njirimara nke ụfọdụ ion metal na-ebuli ihe onwunwe nke aluminum na aluminum alloys. Dịka ọmụmaatụ, Tian Lianpeng [2] ji teknụzụ ntinye ion tinye titanium n'elu aluminom alloy, wee rụọ ọrụ anodization iji nweta ihe nkiri ihe nkiri nke ihe nkiri alumini-titanium mejupụtara nke anodized, nke mere ka elu nke ihe nkiri anodized dịkwuo larịị na otu. , ma kwalite anodization nke aluminum alloy. Njupụta nke ihe nkiri ahụ; Ntinye ion titanium nwere ike imeziwanye nguzogide corrosion nke aluminom alloy anodic oxide film na acid na alkaline NaCl ngwọta, ma ọ dịghị emetụta amorphous Ọdịdị nke aluminum alloy anodic oxide film. Ntinye nickel ion na-eme ka nhazi elu na ọdịdị ọdịdị nke ihe nkiri anodic oxide nke aluminom dịkwuo oke na otu. Nickel agbanyere dị n'ụdị nickel ọla na nickel oxide na ihe nkiri aluminom alloy anodic oxide.

1.2 Chemical oxidation

Chemical oxidation na-ezo aka na usoro mkpuchi nke elu aluminom dị ọcha na-emekọrịta ihe na ikuku oxygen na ngwọta oxidizing site na arụ ọrụ kemịkal n'okpuru ọnọdụ okpomọkụ ụfọdụ iji mepụta ihe nkiri oxide. E nwere ọtụtụ ụzọ oxidation kemịkalụ maka aluminom na aluminom alloys, dị ka ọdịdị nke ngwọta

Enwere ike kewaa ya na alkaline na acidic. Dị ka ọdịdị nke ihe nkiri ahụ si dị, enwere ike kewaa ya na fim oxide, ihe nkiri phosphate, ihe nkiri chromate na ihe nkiri chromic acid-phosphate. Ihe nkiri oxide nwetara site na oxidation chemical nke aluminom na aluminom alloy akụkụ nwere ọkpụrụkpụ nke banyere 0.5 ~ 4μm. Ọ nwere nguzogide iyi adịghị mma yana nguzogide corrosion dị ala karịa ihe nkiri anodic oxide. Ọ naghị adabara iji naanị ya, ma ọ nwere ụfọdụ nguzogide corrosion na ezigbo anụ ahụ. Ike absorption bụ ezigbo primer maka eserese. Agba mgbe kemịkalụ oxidation nke aluminom na aluminom alloy nwere ike imeziwanye ike njikọ dị n'etiti mkpụrụ na mkpuchi, ma welie nguzogide corrosion nke aluminom [3].

1.3 Micro-arc oxidation usoro

A na-akpọkwa teknụzụ micro-arc oxidation dị ka teknụzụ micro-plasma oxidation technology ma ọ bụ teknụzụ mgbaba anode, nke bụ ụdị uto n'ime ọnọdụ site na mwepu micro-plasma n'elu igwe na alloys ya. Oxidation

Nkà na ụzụ ọhụrụ nke akpụkpọ anụ seramiiki. Ihe nkiri dị n'elu nke teknụzụ a hibere nwere ike njikọ siri ike na mkpụrụ, ike siri ike, eyi nguzogide, nguzogide corrosion, nguzogide ujo dị elu, mkpuchi ọkụ eletrik dị mma nke ihe nkiri ahụ, yana voltaji mmebi dị elu. Ọ bụghị naanị nke ahụ, teknụzụ na-anabata usoro kpo oku dị elu nke micro plasma arc kpo oku na oke ume ike dị oke elu, usoro matriks adịghị emetụta, na usoro ahụ adịghị mgbagwoju anya, ọ naghị ebute mmetọ gburugburu ebe obibi. Ọ bụ teknụzụ ọgwụgwọ elu ihe ọhụrụ na-ekwe nkwa. Ọ na-aghọ ebe a na-eme nchọpụta n'ọhịa nke nkà na ụzụ ihe elu ụwa. Zhang Juguo et al.

eji igwe aluminom alloy LY12 dị ka ihe nnwale, ejiri MAO240/750 micro-arc oxidation akụrụngwa, TT260 ọkpụrụkpụ nlele na AMARY-1000B nyocha eletrọnịkị iji mụọ mmetụta nke voltaji arc, njupụta ugbu a na oge oxidation na oyi akwa seramiiki. Mmetụta arụmọrụ. Site na usoro nyocha nke aluminom alloy micro-arc oxidation process tests na Na 2 SiO 3 electrolyte, iwu uto nke ihe nkiri seramiiki oxide n'oge usoro micro-arc oxidation na mmetụta nke ihe mejupụtara electrolyte dị iche iche na itinye uche na ịdị mma nke seramiiki oxide. a na-amụ ihe nkiri. Ihe micro-arc oxidation nke aluminum alloy elu bụ usoro dị mgbagwoju anya, gụnyere nhazi electrochemical nke ihe nkiri mbụ oxide, na nkwụsị nke ihe nkiri seramiiki na-esote, nke gụnyere mmetụta anụ ahụ nke thermochemistry, electrochemistry, ìhè, ọkụ eletrik, na okpomọkụ. .

Usoro na-emetụta ihe nke mkpụrụ ahụ n'onwe ya, ihe ndị na-enye ọkụ eletrik, na ihe ndị na-emepụta ihe na-emepụta ihe, ọ na-esikwa ike nyochaa ịntanetị, nke na-eweta ihe isi ike na nyocha nyocha. Ya mere, ka ọ dị ugbu a, a ka nwere usoro ihe atụ nke nwere ike ịkọwapụta ihe ngosi nnwale dị iche iche nke ọma, na nyocha na usoro ya ka chọrọ nyocha na nkwalite ọzọ.

2 Electroplating na kemịkalụ plating

Electroplating bụ itinye akwa akwa mkpuchi ọla ndị ọzọ n'elu aluminom na aluminom alloy site na usoro kemịkalụ ma ọ bụ electrochemical, nke nwere ike ịgbanwe ihe anụ ahụ ma ọ bụ kemịkalụ nke elu aluminom alloy. elu

Omume ọma; ọla kọpa, nickel ma ọ bụ tin plating nwere ike melite weldability nke aluminum alloy; na tin na-ekpo ọkụ ma ọ bụ aluminom-tin alloy nwere ike melite mmanu nke aluminum alloy; n'ozuzu na-emeziwanye ike elu ma na-eyi nguzogide nke aluminum alloy na chromium plating ma ọ bụ nickel plating; Chrome ma ọ bụ nickel plating nwekwara ike imeziwanye mma ya. Enwere ike ịmegharị aluminum na electrolyte iji mepụta mkpuchi, mana mkpuchi ahụ dị mfe ikpochapụ. Iji dozie nsogbu a, enwere ike itinye aluminom ma kpuchie ya na ngwọta mmiri nwere ihe zinc. Okpokoro imikpu zinc bụ ijikọ aluminom na matrix alloy ya na mkpuchi na-esote. Akwa akwa dị mkpa, Feng Shaobin et al. [7] mụọ ngwa na usoro nke akwa mkpuchi zinc na mkpụrụ aluminom, wee webata teknụzụ kachasị ọhụrụ na ngwa nke usoro imikpu zinc. Electroplating mgbe imikpu na zinc nwekwara ike na-etolite a mkpa porous film n'elu aluminom wee electroplating.

Electroless plating na-ezo aka na nkà na ụzụ na-emepụta ihe nkiri nke a na-etinye mkpuchi ígwè n'elu igwe site na mmeghachi omume kemịkalụ autocatalytic na ngwọta na-ejikọta ya na nnu ígwè na ihe na-ebelata. N'ime ha, nke a na-ejikarị bụ electroless Ni-P alloy plating. Tụnyere usoro electroplating, electroless plating bụ a

Usoro mmetọ dị nnọọ ala, ihe Ni-P alloy nwetara bụ ezigbo ihe ngbanwe maka plating chromium. Otú ọ dị, e nwere ọtụtụ usoro equipments maka electroless plating, ihe oriri bụ nnukwu, ọrụ oge na-adị ogologo, na-arụ ọrụ usoro bụ cumbersome, na àgwà plating akụkụ siri ike na-ekwe nkwa. Dịka ọmụmaatụ, Feng Liming et al. [8] mụọ usoro nkọwapụta maka electroless nickel-phosphorus alloy plating nke na-agụnye naanị usoro ọgwụgwọ dị ka mmebi, imikpu zinc, na ịsacha mmiri dabere na ngwakọta nke 6063 aluminum alloy. Nsonaazụ nnwale na-egosi na usoro ahụ dị mfe, oyi akwa nickel na-enweghị elektrọn nwere nnukwu gloss, ike njikọta siri ike, agba kwụsiri ike, mkpuchi mkpuchi, ọdịnaya phosphorus n'etiti 10% na 12%, na ike nke steeti plating nwere ike iru karịa 500HV. nke dị elu karịa nke anode. oyi akwa oxide [8]. Na mgbakwunye na Ni-P alloy plating enweghị elektrọn, e nwere ndị ọzọ alloy, dị ka Ni-Co-P alloy nke Yang Erbing mụrụ [9]. Ihe nkiri ahụ nwere mmanye dị elu, obere remanence na ntụgharị electromagnetic magburu onwe ya. Atụmatụ, enwere ike iji ya na diski dị elu na mpaghara ndị ọzọ, na-eji plating electroless

Usoro Ni-Co-P nwere ike nweta nha nha na ihe nkiri magnetik na mkpụrụ osisi ọ bụla dị mgbagwoju anya, ma nwee uru nke akụ na ụba, oriri ike dị ala na ọrụ dị mma.

3 mkpuchi ihu

3.1 Laser mkpuchi

N'ime afọ ndị na-adịbeghị anya, iji laser beam lasers maka ọgwụgwọ laser n'elu aluminom alloy elu nwere ike imeziwanye ike ike na iyi nguzogide nke aluminum na aluminum alloy surfaces. Dịka ọmụmaatụ, a na-eji laser 5kW CO 2 na-ekpuchi mkpuchi plasma Ni-WC n'elu ZA111 alloy. Ihe mkpuchi laser enwetara nwere ike siri ike, na mmanye ya, iyi na nguzogide abrasion bụ ugboro 1.75 nke mkpuchi a na-efesa na-enweghị ọgwụgwọ laser yana ugboro 2.83 nke Al-Si alloy matrix. Zhao Yong [11] ji CO 2 lasers na aluminum na aluminum alloy substrates

A na-ekpuchi ya na mkpuchi Y na Y-Al, ntụ ntụ na-ekpuchi elu nke mkpụrụ ahụ site na usoro mkpuchi ntụ ntụ preset, a na-echekwa bat laser site na argon, na ụfọdụ CaF 2, LiF na MgF 2 bụ. agbakwunyere dị ka onye na-akpụ slag N'okpuru ụfọdụ usoro ihe mkpuchi laser, enwere ike nweta otu akwa na mkpuchi mkpuchi na-aga n'ihu nke nwere interface metallurgical. Lu Weixin [12] na-eji CO 2 laser kwadebe mkpuchi ntụ ntụ Al-Si, mkpuchi ntụ ntụ Al-Si + Al-2 O 3 na mkpuchi mkpuchi aluminum alloy site na usoro mkpuchi laser. , Al bronze ntụ ntụ mkpuchi. Zhang Song et al. [13] jiri 2 kW na-aga n'ihu Nd: YAG laser na AA6 0 6 1 aluminum

Elu nke alloy bụ laser cladding na SiC ceramic ntụ ntụ, na elu metal matrix composite (MMC) gbanwetụrụ oyi akwa nwere ike kwadebere n'elu nke aluminum alloy site laser agbaze ọgwụgwọ.

3.2 Ihe mkpuchi mejupụtara

Ihe mkpuchi aluminom nke na-eme onwe ya mmanye onwe ya na ihe mgbochi dị mma na nke na-egbochi ya nwere atụmanya ngwa dị mma na injinia, ọkachasị n'ọhịa nke teknụzụ ịkpụcha. Ya mere, akpụkpọ ahụ alumina porous nwere usoro matriks pore enwetawokwa nlebara anya site n'aka ndị mmadụ. Ntị, aluminom alloy composite mkpuchi teknụzụ aghọwo otu n'ime ebe nyocha ugbu a. Qu Zhijian [14] mụrụ aluminom na 6063 aluminum alloy composite onwe-lubricating teknụzụ mkpuchi. Usoro bụ isi bụ ime anodization siri ike na aluminum na 6063 aluminum alloy, wee jiri usoro ntinye ọkụ na-ekpo ọkụ na-ewebata ihe ndị PTFE n'ime ihe nkiri oxide. Na elu, mgbe ọgwụgwọ kpomkwem ziri ezi okpomọkụ, a na-emepụta mkpuchi ihe mejupụtara. Li Zhenfang [15] nyochara usoro ọhụrụ ijikọ mkpuchi agba resin na usoro electroplating n'elu wiil alloy aluminom etinyere na ụgbọ ala. Oge ule CASS bụ awa 66, ọnụ ọgụgụ na-egbuke egbuke bụ ≤3%, ọnụọgụ ọla kọpa bụ ≤3%, nguzozi ike na-ebelata site na 10 ~ 20g, na agba resin na mkpuchi metal nwere ọdịdị mara mma.

4 Ụzọ ndị ọzọ

4.1 ion usoro ntinye

Usoro ntinye ion na-eji ion ion ike dị elu na-atụba ihe mgbaru ọsọ na ọnọdụ enweghị ohere. Enwere ike ime ihe fọrọ nke nta ka ọ bụrụ ion ọ bụla. A na-ewepụ ion ndị ahụ etinyere ma hapụ ya n'ọnọdụ nnọchi ma ọ bụ ọnọdụ oghere nke ngwọta siri ike iji mepụta oyi akwa na-enweghị isi. Aluminom alloy

A na-emeziwanye ike ike nke elu, nguzogide iyi na nguzogide corrosion. Magnetron sputtering dị ọcha titanium sochiri PB11 nitrogen/carbon ntinye nwere ike imeziwanye microhardness nke elu gbanwetụrụ. Mgbasa Magnetron jikọtara ya na ntụtụ nitrogen nwere ike ịbawanye ike nke mkpụrụ sitere na 180HV ruo 281.4HV. Mgbasa Magnetron jikọtara ya na ntụtụ carbon nwere ike ịbawanye ruo 342HV [16]. Magnetron sputtering dị ọcha titanium sochiri PB11 nitrogen/carbon ntinye nwere ike imeziwanye microhardness nke elu gbanwetụrụ. Liao Jiaxuan et al. [17] rụrụ ihe mejupụtara titanium, nitrogen, na carbon na ndabere nke ion nke dabeere na plasma nke LY12 aluminum alloy, wee nweta mmetụta mgbanwe dị ịrịba ama. Zhang Shengtao na Huang Zongqing nke Mahadum Chongqing [18] mere ntinye titanium ion na aluminom alloy. Nsonaazụ gosiri na ntinye nke titanium ion n'elu aluminom alloy bụ ụzọ dị irè iji meziwanye nguzogide ya na ion corrosion chloride, ma nwee ike imeziwanye ikike nke aluminum alloy iguzogide ion corrosion chloride. Gbasawanye ikike ngafe nke aluminom alloy na NaCl na ngwọta ndị ọzọ, ma belata njupụta na nha nke pores corrosion mebiri site na ion chloride.

4.2 mkpuchi ngbanwe ụwa dị ụkọ

Mkpuchi ntughari elu ala na-adịghị ahụkebe nwere ike melite nguzogide corrosion nke aluminom alloys, na usoro a na-abụkarị imi kemịkal. Ụwa na-adịghị ahụkebe bara uru na aluminum alloy anodic oxidation. Ọ na-eme ka ike nke aluminum alloy na-anabata polarization ma n'otu oge ahụ na-eme ka ihe mgbochi corrosion nke ihe nkiri oxide dịkwuo mma. Ya mere, a na-eji ụwa na-adịghị ahụkebe eme ihe

Ngwọta elu aluminom alloy nwere atụmanya mmepe dị mma [19]. Shi Tie et al. [20] mụọ usoro nke imepụta ihe nkiri ntụgharị nnu cerium n'elu aluminom LF21 na-egosi nchara site na ntinye electrolytic. A na-eji nnwale orthogonal mee ihe iji mụọ mmetụta nke ihe ndị metụtara ya na usoro mmepụta ihe nkiri ahụ ma nweta paramita teknụzụ kachasị mma. Nsonaazụ na-egosi na a na-egbochi usoro corrosion anodic nke aluminom na-enweghị nchara mgbe ọgwụgwọ nke electrolytic deposition nke ihe nkiri ntụgharị ụwa na-adịghị ahụkebe, a na-eme ka nguzogide corrosion ya dịkwuo mma, na hydrophilicity na-emekwa ka ọ dịkwuo mma. Zhu Liping et al. [21] eji nyocha eletrọnịkị microscopy (SEM), ike spectroscopy (EMS) na ụzọ nnwale nnu iji mụọ usoro, nhazi na kọmpat nke aluminum alloy obere cerium nnu ngbanwe mkpuchi na nguzogide corrosion ya. Mmetụta. Nsonaazụ nchọcha a gosiri na cerium cerium dị ụkọ n'ime ihe nkiri a na-egbochi omume corrosion nke aluminom na-eme ka ọ dịkwuo mma.

Nguzogide corrosion na-arụ ọrụ dị mkpa. N'oge a, e nwere usoro ọgwụgwọ dị iche iche nke aluminum na aluminum alloys, na ọrụ ha na-esiwanye ike ma na-esiwanye ike, nke nwere ike izute mkpa nke aluminum na aluminum alloys na ndụ, ọgwụgwọ ahụike, injinia, ikuku, ngwá ọrụ, ngwá electronic, nri na ụlọ ọrụ ọkụ, wdg chọrọ. N'ọdịnihu, ọgwụgwọ elu nke aluminom na aluminom alloys ga-adị mfe na nhazi usoro, kwụsie ike n'ịdị mma, nnukwu, nchekwa ike, na gburugburu ebe obibi.

Mmepe ntụziaka. Ọ bụ ngọngọ copolymer nke mmeghachi omume mgbanwe ester-amide nwere ọnụego mgbanwe dị elu. Korshak et al. [11] kọrọ na mgbe a na-eji 1% PbO 2 ma ọ bụ 2% PbO 2 mee ihe dị ka ihe na-eme ka ọ dị ọkụ na 260 degrees maka 3-8 awa, mmeghachi omume n'etiti polyester na polyamide ga-emekwa. Mmeghachi omume mgbanwe ester-amide nwere mmetụta ụfọdụ na ndakọrịta nke usoro ngwakọta. Xie Xiaolin, Li Ruixia, wdg [12] iji ngwọta

Usoro, nhazi ngwa ngwa dị mfe (usoro agbaze 1) na ọnụnọ nke ester-amide mgbanwe mmeghachi omume ngwakọta usoro (usoro agbaze) iji jikọta PET na PA66, nyocha DSC n'usoro, na ndakọrịta nke usoro ngwakọta PET/PA66 A tụlere mmekọahụ ruo n'ókè ụfọdụ. Nsonaazụ na-egosi na usoro ngwakọta PET/PA66 bụ usoro na-ekwekọghị ekwekọ, na ndakọrịta nke ngwakọta agbaze dị mma karịa nke ngwakọta ngwọta, na ngọngọ copolymer nke ngwakọta PET/PA66 mepụtara na-adaba na abụọ. emewo ka mma; na mmụba nke ọdịnaya PA66, ebe mgbaze nke ngwakọta ebelatala. Ihe mgbochi PET/PA66 nke copolymer mebere site na mmeghachi omume na-abawanye mmetụta nucleation nke PA66 na kristal oge PET, na-eme ka agbaze kristal nke ngwakọta French dị elu karịa nke usoro mgbaze 1. Zhu Hong et al. [13] jiri p-toluenesulfonic acid (TsOH) na ndị na-ejikọta titanate dị ka ihe na-akpata mmeghachi omume mgbanwe ester-amide n'etiti Nylon-6 na PET iji nweta nkwekọ n'ime ọnọdụ nke ngwakọta Nylon-6/PET. Ebumnuche nke nyocha nyocha microscope eletrọn na-egosi na ngwakọta naịlọn-6/PET bụ usoro nkewa nke kristal na enweghị ndakọrịta. Ịgbakwunye p-toluenesulfonic acid na titanate njikọ ọnụ dị ka ihe na-akpali akpali iji kwalite n'ime ebe ngọngọ guzobe Copolymer na-eme ka njikọ njikọ dị n'etiti akụkụ abụọ ahụ, na-eme ka a nụchara anụcha na-ekesa n'otu n'otu, ma na-enyere aka ịbawanye ọrụ mgbasawanye nke ngwakọta. . Ha abụọ na-enyere aka melite ndakọrịta nke ngwakọta na ịbawanye nchikota interfacial nke akụkụ abụọ ahụ.

Ihe ngosi 2

N'ime afọ ndị na-adịbeghị anya, ndị na-eme nchọpụta ụlọ emeela ọtụtụ ọrụ nyocha na ngwakọta polyamide / polyester ma nweta ọtụtụ nkwubi okwu bara uru, na-etinye ntọala dị mma maka nyocha n'ọdịnihu na mpaghara a. Ka ọ dị ugbu a, ihe kwesịrị ịṅa ntị bụ ịkwalite mmepe mmepe nke ihe ngwakọta polyamide / polyester ma tinye nkwubi okwu gara aga na omume mmepụta n'ezie. Site n'ịgbanwe ihe abụọ ahụ, a na-enweta ihe ọhụrụ nke na-akwado uru nke akụkụ abụọ ahụ. O nwere ihe eji arụ ọrụ nke ọma, nguzogide mmiri dị mma karịa polyamide, na mmetụta siri ike dị mma karịa polyester. A na-eji ya eme ihe na ngwa elektrọnik, eletriki na ụlọ ọrụ ụgbọ ala. ngwa.

Njikọ na akụkọ a : Teknụzụ Ọgwụ Elu nke Aluminom Alloy

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

PTJ® na-enye a nso nke Omenala nkenke chnc machining china ISIS 9001: 2015 & AS-9100 kwadoro. 3, 4 na 5-axis ngwa ngwa nkenke CNC igwe ọrụ gụnyere igwe, na-echigharịkwuru nkọwa ndị ahịa, Ike nke metal & plastic machined akụkụ na +/- 0.005 mm ..Sekondary ọrụ gụnyere CNC na ot egweri, mkpọpu ala,nwụọ ịtụwa,mpempe akwụkwọ na stampụNa-enye ihe omuma, mmeputa zuru oke, nkwado oru na nyocha zuru oke akpakanamde, ụgbọelu, ebu & eletrik, Ikanam ọkụ,ọgwụ, igwe kwụ otu ebe, na ndị na-azụ ahịa ngwá electronic ụlọ ọrụ. On-nnyefe: -Gwa anyị obere ihe gị ngo si mmefu ego na-atụ anya nnyefe oge. Anyị ga-putara ighe gị iji nye ndị kasị na-eri-irè ọrụ na-enyere gị aka iru gị iche, Mmadụ Bịa kpọtụrụ anyị ( sales@pintejin.com ) ozugbo maka oru ohuru gi.

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

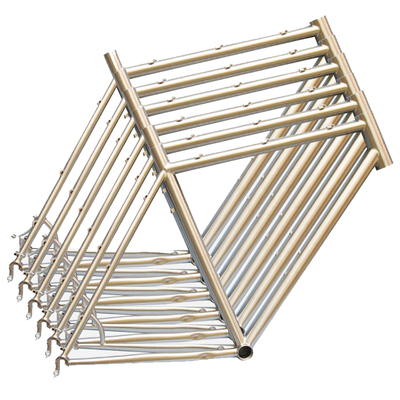

- Akụkụ Bicycle

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo