Ngwọta nke nrụrụ maka akụkụ CNC na-atụgharị obere mgbidi

2021-10-23

N'ime usoro CNC na-atụgharị, a na-edozi ụfọdụ akụkụ ndị nwere mgbidi dị mkpa. Mgbe ị na-atụgharị workpieces dị obere, n'ihi adịghị ike nke arụ ọrụ ahụ, nrụrụ nke workpieces nwere mgbidi na CNC lathes bụ ihe ndị na-esonụ n'oge usoro ntụgharị.

- 1. N'ihi na mkpa mgbidi nke workpiece, ọ dị mfe deform n'okpuru omume nke clamping mgbali. Si otú ahụ na-emetụta akụkụ ziri ezi na ọdịdị ọdịdị nke workpiece. Mgbe ị na-eji chuck-jaw atọ dị ka egosiri na Figure 1 iji kụchie workpiece iji hazie oghere dị n'ime, ọ ga-adị ntakịrị ka ọ bụrụ triangle n'okpuru ọrụ nke ike njide, mana a na-enweta oghere cylindrical mgbe ọ gbachara oghere ahụ. Mgbe agba na-ahapụ na workpiece wepụrụ, mpụta gburugburu na-alaghachi a cylindrical udi n'ihi na-agbanwe mgbake, mgbe n'ime oghere na-aghọ arc ekara triangle dị ka e gosiri na Figure 2. Mgbe ịlele na esịtidem micrometer, na dayameta. D n'akụkụ niile hà nhata.

- 2. N'okpuru omume nke ịkpụ ike (karịsịa radial ọnwụ ike), ọ dị mfe ịmepụta vibration na deformation, nke na-emetụta akụkụ ziri ezi, ọdịdị, ọnọdụ ziri ezi na elu roughness nke workpiece.

- 3. N'ihi na workpiece dị mkpa, okpomọkụ nke ịkpụ ga-eme ka thermal deformation nke workpiece, nke na-eme ka o siri ike ịchịkwa size nke workpiece. N'ihi na metal mkpa-walled workpieces na nnukwu linear mgbasa ọnụọgụ, dị ka na-aga n'ihu ọkara-mechara mbịne na-emecha mbịne na otu echichi, thermal deformation nke workpiece mere site ọnwụ okpomọkụ ga-mmetụta nke ukwuu akụkụ ziri ezi, na mgbe ụfọdụ ọbụna na-eme ka workpiece. Rapaara na nkwụnye ahụ.

Anyị maara ka esi edozi workpieces mkpa nwere mgbidi site na CNC lathes, yabụ kedu ihe anyị kwesịrị ime maka nrụrụ nke workpieces dị mkpa na CNC lathes? A kọwara ọtụtụ ngwọta n'okpuru.

- 1. The workpiece na-ekewa n'ime ike ike akụkụ. N'oge mgbagharị siri ike na ogbo ntụgharị n'ikpeazụ, n'ihi oke mbepụ ka ukwuu, ike njigide dị ntakịrị karịa, na nrụrụ ahụ na-abawanye nha anya; n'oge ntụgharị na-agwụcha, ike nkedo ahụ nwere ike ịdị ntakịrị ntakịrị, na n'otu aka ahụ, ihe nkedo ahụ na-emeziwanye. N'aka nke ọzọ, ọ nwekwara ike iwepụ nrụrụ nke oke ike ịkpụ n'oge ntụgharị siri ike.

- 2. Mgbe ị na-eji geometric parameters ka ezi-atụgharị mkpa-walled workpieces ezi uche, na rigidity chọrọ ịdị elu, na wiper agụba adịghị mfe ịdị ogologo (na-emekarị 0.2-0.3mm), na mbepụ ọnụ kwesịrị nkọ.

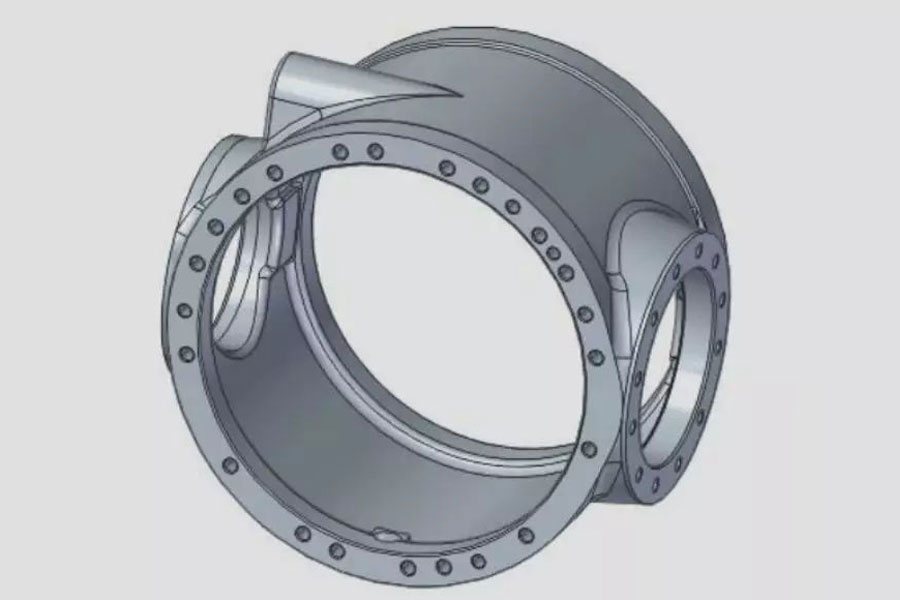

- 3. Mee ka elu kọntaktị na-amachi aka dị ka egosiri na foto 3. Jiri aka mgbawa ma ọ bụ ụfọdụ agba dị nro pụrụ iche. A na-amụba elu kọntaktị ahụ, nke mere na a na-ekesa ike nkedo na-arụ ọrụ nke ọma, nke mere na ọrụ ahụ adịghị mfe nrụrụ n'oge clamping.

- 4. Na-awụpụ mmiri nke ịkpụ n'ụzọ zuru ezu. Site n'ịwụsa mmiri mmiri n'ụzọ zuru ezu, belata ọkụ ọkụ ma belata nrụrụ ọkụ nke workpiece.

- 5. Mmụba ọgịrịga usoro. Ụfọdụ mkpa-walled workpieces na-pụrụ iche mere na ọtụtụ usoro ọgịrịga na clamping ọnọdụ welie rigidity ebe a, nke mere na clamping ike na-eme na usoro ọgịrịga iji belata deformation nke workpiece. Mgbe emechara nhazi ahụ, a na-ewepụ ọgịrịga usoro ahụ. .

- 6. Mgbe axial clamping ndozi ekwesịrị iji ya mee ihe na-arụ ọrụ nke nwere mgbidi dị mkpa, radial clamping ekwesịghị iji ya mee ihe dị ka o kwere mee, na usoro axial clamping nke egosiri na Figure 4 ka mma. The workpiece na-clamped axially site na njedebe ihu axial clamping aka uwe (threaded aka uwe). Ebe ọ bụ na a na-ekesa ike clamping F n'akụkụ axial direction nke workpiece, axial rigidity nke workpiece bụ nnukwu, na ọ dịghị mfe ịmepụta clamping deformation.

Njikọ na akụkọ a :Ngwọta nke nrụrụ maka akụkụ CNC na-atụgharị obere mgbidi

Nkwupụta Mbipụta: Ọ bụrụ na enweghị ntuziaka pụrụ iche, isiokwu niile dị na saịtị a bụ nke mbụ. Biko gosi isi mmalite maka ibipụta ya ọzọ: https: //www.cncmachiningptj.com/,thanks!

3, 4 na 5 axis nkenke CNC igwe ọrụ maka ígwè machining, beryllium, carbon ígwè, magnesium, titanium igwe, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite na osisi. Ike nke machining akụkụ ruo 98 na. Mbịne dia. na +/- 0.001 n'ime. ndidi kwụ ọtọ. Usoro gụnyere egwe ọka, ịtụgharị, igwu ala, na -agwụ ike, ịpịkọta, ịme ọpịpị, ịkpụ, ijikọ ọnụ, mbadamba ihe, ịtụgharị uche, ịtụgharị na ọnwu laser. Ọrụ nke abụọ dị ka mgbakọ, egweri enweghị ebe etiti, ọgwụgwọ ọkụ, plating na ịgbado ọkụ. Prototype na mmepụta olu dị ala na -enye ya nwere nkeji 50,000 kacha. Kwesịrị ekwesị maka ike mmiri, pneumatics, hydraulics na valvụ ngwa. Ọ na-eje ozi ụgbọelu, ụgbọ elu, ndị agha, ụlọ ọgwụ na ụlọ ọrụ nchekwa. sales@pintejin.com ) ozugbo maka oru ohuru gi.

3, 4 na 5 axis nkenke CNC igwe ọrụ maka ígwè machining, beryllium, carbon ígwè, magnesium, titanium igwe, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite na osisi. Ike nke machining akụkụ ruo 98 na. Mbịne dia. na +/- 0.001 n'ime. ndidi kwụ ọtọ. Usoro gụnyere egwe ọka, ịtụgharị, igwu ala, na -agwụ ike, ịpịkọta, ịme ọpịpị, ịkpụ, ijikọ ọnụ, mbadamba ihe, ịtụgharị uche, ịtụgharị na ọnwu laser. Ọrụ nke abụọ dị ka mgbakọ, egweri enweghị ebe etiti, ọgwụgwọ ọkụ, plating na ịgbado ọkụ. Prototype na mmepụta olu dị ala na -enye ya nwere nkeji 50,000 kacha. Kwesịrị ekwesị maka ike mmiri, pneumatics, hydraulics na valvụ ngwa. Ọ na-eje ozi ụgbọelu, ụgbọ elu, ndị agha, ụlọ ọgwụ na ụlọ ọrụ nchekwa. sales@pintejin.com ) ozugbo maka oru ohuru gi.

anyị Ọrụ

- 5 Axis igwe

- Mkpo Cnc

- CNC agbanye

- Ụlọ ọrụ igwe

- Usoro Machining

- Ọgwụgwọ Ọgwụ

- Igwe igwe

- Plastic igwe

- Ntụ ntụ Metallurgy akpụzi

- Nkedo nke Anwụ

- Akụkụ osisi

ikpe Studies

- Akụkụ igwe akpaaka

- Akụkụ Mpịakọta

- Heatsink LED

- Ihe owuwu

- Akụkụ mkpanaka

- Akụkụ Ahụike

- Elektrik Parts

- Ejiri Machining

- Akụkụ Bicycle

Ndepụta Ihe

- Aluminium igwe

- Nhazi Titanium

- Igwe anaghị agba nchara machining

- Ọla kọpa

- Ngwongwo ọla

- Ngwunye Super Alloy

- Peek igwe

- Ụlọ ọrụ UHMW

- Ịrụ Ọrụ Pụrụ iche

- PA6 igwe

- Nhazi PPS

- Ngwongwo Teflon

- Inconel igwe

- Ngwá Ọrụ Ngwá Ọrụ Ngwá Ọrụ

- Ihe ndi ozo

Akụkụ osisi